A peristaltic pump is used for solving difficult fluid handling problems and is especially useful when handling sterile, shear-sensitive or high-purity fluids. The design inherently exposes the fluid to only one component — the tubing — which can be specifically selected for the liquid being pumped or regulatory requirements. Exposure to only one component ensures compatibility of the fluid path when the correct tubing material is selected. This prevents contamination and early failure of the tubing. The peristaltic pump can pump continuously or dispense in defined amounts. The peristaltic pump system is a positive displacement pump and includes three components: the drive, pump head and tubing.

How do peristaltic pumps work?

Since the tubing is the only system component that comes in contact with the fluid, peristaltic pumps are easy to clean, have excellent priming abilities and are well-suited for many different applications from chemical feed to medical devices and pharmaceutical production. However, when the tubing is replaced for preventive maintenance or a new single-use application, operators are required to open the pump head. This action exposes the rollers.

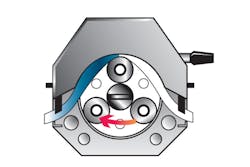

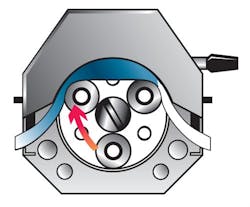

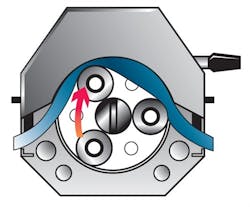

Figure 2. The rollers on the rotor move across the tubing, pushing the fluid. The tubing behind the rollers recovers its shape, creates a vacuum and draws fluid in behind it.

Until recently, most peristaltic pumps relied on the operator to shut down or turn off the pump motor prior to servicing. This is considered a standard operating procedure when working with electromechanical devices. Cutting the power or shutting down helps prevent inadvertent operation of the device.

Figure 3. A "pillow" of fluid is formed between the rollers. This is specific to the inside diameter of the tubing and the geometry of the rotor. Flow rate is determined by multiplying speed by the size of the pillow. This pillow stays fairly constant except with extremely viscous fluids.

Peristaltic pumps need to have the tubing serviced and replaced periodically. In some older pumps, the pump head needs to be removed to replace the tubing. Newer pumps with easy loading capability allow the operator to replace the tubing with the pump head still mounted to the drive. With this advancement, the potential for exposure to a rotating rotor became evident. The industry’s increasing regulatory and safety focus drove an opportunity for improving workplace ergonomics and the development of the open-head sensor interlock feature.

A typical pump system equipped with an open-head sensor interlock. The pump and drive form an integrated package that stops pump rotation when the head is opened.

Providing an extra layer of protection

Integrated open-head sensor interlocks provide added protection for technicians and operators tasked with tubing changes and routine maintenance in busy production environments. This new feature is particularly beneficial for peristaltic pumps operating in a system where a programmable logic controller (PLC) or supervisory control and data acquisition (SCADA) system can control the pumps from a remote location. Unexpected remote actuation of the pump is prevented by the open-head sensor interlock, similar to lockout/ tagout procedures. Openhead sensor interlocks can also safeguard inexperienced or infrequent users of peristaltic pumps from injury while loading or changing tubing. This sensor technology couples with quick-loading pump heads to shut down the drive when the pump head is opened, eliminating the exposure to moving rollers connected to the drive shaft.

An open-head sensor interlock and drive connection

In addition, a stand-alone sensor system is an option for owners who have peristaltic pumps without integrated open-head sensor interlocks. When an operator opens the pump head (intentionally or accidentally), power is removed from the pump drive that is connected to an interlock box. Power to the pump drive will not be restored until the operator closes the pump head.

The stand-alone system is comprised of an interlock control box and a new open-head sensor interlock pump head. The pump head with the open-head sensor interlock easily connects to the interlock control box that houses a control board that contains suitable relays for cutting off line voltage when the pump head is opened. If the pump head is opened during operation, the interlock control box instantly shuts down the drive. Power to the pump drive will not be restored until the operator closes the opened pump head. An indicator light on the box provides a visual status of the condition of the sensed head.

A stand-alone system allows peristaltic pumps in the field to be equipped with the open-head sensor interlock feature.

The interlock control box on the stand-alone system accepts input signals from up to two stacked pump heads and will respond to either head being opened. The box is supplied with a sensor-shorting plug to allow single-channel operation. When dual channel is desired, this plug is removed and the second head is connected. This stand-alone system is also NEMA 4X/IP66-rated for washdown, making it ideal for food processing and other industries that have critical cleaning protocols.

The open-head sensor interlock and stand-alone system can play an important part in protecting technicians and operators who work with peristaltic pumps. The technology will enhance workplace safety as more companies continue to add the feature to their peristaltic pump fleets.

Gregg E. Johnson is the global senior product manager for the Cole-Parmer Masterflex and Ismatec product lines. He has worked in the pump industry for more than 30 years, and specifically with peristaltic pumps for more than 19 years.