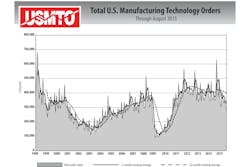

U.S. manufacturing technology orders were down from July to August, according to a report from The Association For Manufacturing Technology (AMT). The total of orders, $285.92 million, was 10.2 percent less than July’s $318.48 million and 21.2 percent less than $362.65 million reported in August 2014.

The year-to-date total for manufacturing orders for 2015, $2,771.23 million, is down 10 percent when compared with 2014. All of these figures are based on the totals of data reported by companies participating in the USMTO program.

"While there is a sense of unease in manufacturing now as indicated by this reduction in orders combined with drops in the PMI [purchasing managers index] and industrial production, some leveling after a period of strong growth is expected and helps build stable longer term growth," said AMT President Douglas K. Woods, in a statement released with the monthly USMTO report. "We are a diversified industry, and pockets of manufacturing continue to show resilience, such as automotive stamping and medical devices. While there is some cause for caution, we do not anticipate more than market flatness into the early part of 2016."

The United States Manufacturing Technology Orders (USMTO) report, compiled by the trade association representing the production and distribution of manufacturing technology, provides regional and national U.S. orders data of domestic and imported machine tools and related equipment. According to AMT, analysis of manufacturing technology orders provides a reliable economic indicator as manufacturing industries invest in capital metalworking equipment to increase capacity and improve productivity.