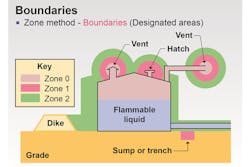

Figure 2. Plant diagram. Control stations and panels should be located outside of Zone 0 whenever possible, which often requires relocation to just a few feet away. Graphic courtesy of IDEC

In process plants and some other industrial settings, certain areas are classified as hazardous because of the presence of flammable gases and vapors, and they require following detailed control panel design standards to ensure safety and reliability. This article looks at various ways to design these panels so they do not become potential ignition sources, and it will use the International Electrotechnical Commission (IEC) Zone hazardous area classification system instead of the National Electrical Code or other systems.

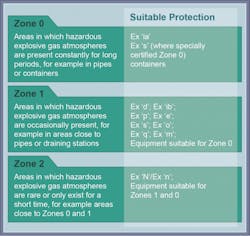

As Figure 1 depicts, the IEC Zone system classifies areas based on the ignitable concentrations of flammable gases or vapors. Zone 0 is the most hazardous area, followed by Zone 1 and then Zone 2.

Figure 1. IEC Zone classification system. The IEC Zone system classifies areas according to the expected presence of hazardous atmospheres. Graphic courtesy of IDEC

It’s much more expensive, complex and time-consuming to design, fabricate and maintain control panels for use in Zone 0 than Zone 1 or 2, so the first step is to try and locate all control panels outside of Zone 0 areas. This can often be accomplished by moving panels a short distance, often only a few feet.

Figure 2 shows a typical zone classification scheme for a process plant. Zone 0 areas are only those inside or right next to vessels or pipes, with Zone 1 areas in relatively close proximity to Zone 0, and Zone 2 areas a bit farther away.

Once all panels have been located to the least restrictive zone possible, the three main design methods for compliance can be considered:

Image 1. Control station. Buying preassembled control stations such as this IDEC unit, in either standard or custom configurations, eliminates design expense for Zone 1 and 2 installations. Graphic courtesy of IDEC

Use Zone 1 and 2 components and enclosures

Using properly rated components and enclosures is the simplest method for compliance in Zone 1 and 2, although not suitable for Zone 0 in most cases because of the lack of availability of Zone 0-rated components. Any control panel suitable for installation in Zone 1 will also be suitable in Zone 2, so the focus of the rest of this article will be on Zone 1. The enclosure and the components should all be specified for use in Zone 1, and the panel design should also meet Zone 1 requirements.

This method works well for smaller and simpler control panels — often referred to as control stations — populated with pushbutton, switch and indicator light devices. However, it often does not work well for enclosures populated with more complex components such as programmable logic controllers (PLCs), motor drives and human machine interfaces (HMIs) because many of these components are not available with proper ratings. For example, a company’s preferred make and model PLC may not be certified for use in Zone 1.

Preassembled Zone 1 standard control stations populated by an assortment of rated pushbuttons, switches and lights are available from some suppliers (see Image 1). These suppliers will build customized control stations, providing end users and integrators with the ability to tailor the panel to their exact requirements, saving time and reducing cost. Buying preassembled Zone 1 control stations, either standard or custom, eliminates design expense.

Once Zone 1 control stations or control panels are specified or designed — and then installed — maintenance is minimal, and years of trouble-free service can be expected. The cost of designing with this method of protection, as well as the cost of the components, is considerably less than the next two methods of protection for most control panels. And as mentioned, panel design costs are eliminated when ordering preassembled control stations, an option not available with the other two protection methods.

Image 2. Air-purge systems. An air-purge system can be used to allow installation of general-purpose automation devices and components in a Zone 1 area. Image courtesy of Pepperl+Fuchs

Air-purge systems

Another popular protection method is an air-purge system (see Image 2), which is suitable for Zone 1 but not Zone 0. These systems supply air or an inert gas to the enclosure to maintain a positive internal pressure with respect to the environment, thereby preventing flammable gasses or vapors from entering the enclosure. Because the enclosure is under positive pressure, general-purpose enclosures, devices and components can be used.

Designing these systems is a bit more complex than simply specifying Zone 1-rated enclosures, devices and components. Different zones require different types of purge systems, with costs increasing as the zone becomes more hazardous. For example, a purge system allowing the use of general-purpose components in Zone 1 is more expensive than one which allows the use of Zone 2 components in Zone 1.

These systems are not practical for small, simple control stations because the cost of the purge system does not decrease in linear proportion to the enclosure size, but instead has a relatively high minimum price. On the other hand, purge systems work well for larger and more complex control panels, particularly those populated by more complex components such as PLCs, motor drives and HMIs. This is because they allow nonrated, general-purpose components to be installed in Zone 1, a feature not available with the other two methods of protection.

Maintenance consists of making sure the air purge system operates as designed, a task made simpler by systems with pressure gauges or transmitters to ensure positive pressure is maintained. A gauge must be manually monitored to ensure correct pressure, while a transmitter can send a signal proportional to pressure to a remote monitoring and control system, easing maintenance.

If a panel needs to opened for any reason, such as for the repair or replacement of a component, pressure and protection are lost. Consequently, the entire area must first be made safe with respect to the presence of flammable gases or vapors. This can be problematic since it often requires a partial or full shutdown of the plant area.

Intrinsic safety

This method of protection limits the amount of electrical energy which can be released to a level insufficient to ignite flammable gases or vapors. This is the only method of protection suitable for Zone 0, and it works in any Zone 1 or 2 area.

The design of these systems is much more complex than the previous two protection methods because every component must be carefully selected to make sure it is intrinsically safe. The electrical energy delivered by wiring to these components from outside Zone 0 must be limited to levels insufficient to ignite flammable gases or vapors. Intrinsic safety barriers are commonly used for this purpose.

With proper precautions regarding tools and work methods, maintenance can be performed on any component without the need to make sure the area is free of flammable gases or vapors. This is possible because each component in the system cannot release electrical energy sufficient to ignite flammable gases or vapors.

Conclusion

In the past, most Zone 1 installations used either air-purge systems or intrinsic safety protection methods. This has changed in recent years because of the more widespread availability of devices, components and enclosures rated for use in Zone 1.

Pushbuttons, switches, lights, panel meters and other simple devices are widely available with Zone 1 ratings, and the variety of devices available for use in these areas has grown rapidly over the past few years.

The Zone 1 product offerings continue to grow as some suppliers now offer more complex components such as PLCs, HMIs and power supplies with this rating. It is now possible to design a complex control panel for use in Zone 1 by simply be selecting the right devices and components and by following some simple design guidelines.

Preassembled Zone 1 standard and custom control stations populated by an assortment of pushbuttons, switches and lights are also available. This expanded array of options makes it simpler to design control stations and panels for Zone 1 while reducing upfront and maintenance costs.

Jim Dunn is product manager at IDEC. Visit idec.com for more information.