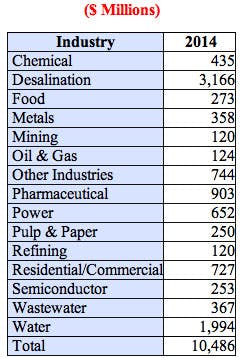

According to the RO, UF, MF World Market report, desalination is the biggest segment and is growing at 11 percent per year compared to 6 percent for the industry as a whole. This growth rate is exclusive of inflation. The market in China is growing faster than in any other nation. China plans to more than triple its production to 2.2 million cubic meters a day by 2015. China is also the largest purchaser of cross-flow membranes for the power industry in which boiler feedwater must be ultrapure.

Reverse-osmosis (RO) is utilized in desalination, boiler feedwater, injectable pharmaceutical fluids and for purification of wastewater for reuse. Ultrafiltration is used for purification of water and wastewater and separation of products in the food and beverage industry. Microfiltration is edging out granular media filters as a method for purifying water for drinking purposes. A process for combining membrane filtration and biological treatment in one vessel is being widely used. Membrane bioreactors (MBR) are used to purify wastewater where the distance to the city wastewater treatment plant is high.

A further use of membrane technology is in sewer mining. A golf course can extract sewage from the pipeline and process it in a cross-flow membrane system. The product is then used to water the golf course while the reject is returned to the sewer line. The biotechnology industry uses microfiltration to separate products.

For more information on RO, UF, MF World Market, click here.