Flowmeters for oil and gas measurement have many applications. These include allocation metering, check metering, process measurement, flare and stack gas measurement, district heating, LNG measurement, and shale gas measurement. Different flow technologies are used for these applications, but custody transfer is one of the most important applications.

Custody transfer occurs when the possession of a fluid, such as oil, gas, water, or steam, changes hands from one owner to another. The owner could, for example, be an oil or gas production company, a pipeline company, or a utility company. What typically happens in a custody-transfer flow measurement situation is that one or two custody-transfer flowmeters measure the volume or mass of fluid before the transfer is made, and then another set of flowmeters measures the flow after the transfer. What makes custody transfer unique among flowmeter applications is that money changes hands and that accuracy requirements are higher than they are for most other applications.

AGA Approvals

Custody-transfer applications have become increasingly important in oil and gas flow measurement. The American Gas Association (AGA, www.aga.org) began studying custody transfer for natural gas applications in the late 1920s. Its first report, called AGA-1, was issued in 1930. AGA-1 dealt with the use of differential-pressure flowmeters with orifice plates for custody-transfer applications. This report was the predecessor of AGA-3, which was first issued in 1955 and reissued in 1992. In 1981, the AGA issued a report on the use of turbine flowmeters for custody-transfer applications. This report applied to gas applications. It was called AGA-7, and it was reissued in 2006. Prior to that, the AGA published AGA-11 in 2003, a report on the use of Coriolis flowmeters for custody-transfer applications.

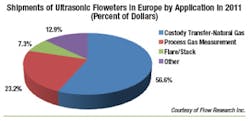

The move to standardize the use of ultrasonic flowmeters for custody transfer began in Europe in the mid-1990s. At that time, Groupe Europeen de Recherches Gaziers (GERG) published Technical Monograph 8, which laid out the criteria for using ultrasonic flowmeters for custody-transfer applications. Following this, the AGA published AGA-9 in 1998, which also specified custody-transfer applications for ultrasonic flowmeters. Though it took some time for this standard to be widely accepted, it has created a surge in the use of ultrasonic flowmeters for custody transfer, especially for natural gas pipeline applications.

API Approvals

While the AGA and the American Petroleum Institute (API) work together on many standards projects, the AGA is more focused on industrial and natural gas, while the API focuses more on petroleum liquids. It should not be surprising, then, that the API has issued its own reports on the use of flowmeters involving custody transfer of liquids. These include API MPMS 5.2 (positive-displacement meters), API MPMS 5.3 (turbine meters), API MPMS 5.6 (Coriolis flowmeters) and API MPMS 5.11 (ultrasonic flowmeters). Other API reports address the use of vortex, magnetic, thermal dispersion, and variable-area flowmeters.

Coriolis Flowmeters

Coriolis flowmeters are used for custody-transfer of both liquids and gases, but they traditionally have had a more difficult time measuring gas than liquid. This is because gas is less dense than liquid, and Coriolis meters operate by measuring the impact of a flowing fluid on a vibrating tube. The main limitation on custody transfer for natural gas is line size, since in the past nearly all Coriolis meters were sold for line sizes of six inches or less. Because many of the line sizes for upstream oil & gas applications are above six inches, most Coriolis meters will not work for these applications. However, they are widely used for both compressed natural gas (CNG) and liquefied natural gas (LNG) applications.

Coriolis flowmeters are widely used for custody transfer of petroleum liquids, especially for downstream applications. They are used to measure the transfer of fuel and other petroleum liquids from trucks to planes, trains, ships, and also to buildings. The line sizes for these applications are much smaller than for upstream applications, and they are well-suited to Coriolis meters. Here Coriolis meters mainly compete with positive-displacement meters. They are replacing positive-displacement meters for some applications because of their high accuracy and reliability, and because, unlike positive-displacement meters, they have no moving parts.

One important development for Coriolis meters is the introduction of large flowmeters for line sizes of 8–16 inches. While most of these meters are designed for petroleum liquids, some are also being developed for gas flow measurement. These meters are still not large enough to compete with turbine and ultrasonic meters for large natural gas pipeline measurement, many of which are 20 inches and above. However, they are likely to make an impact on flow measurement for some upstream oil and gas applications. While not all the large Coriolis meters are for custody transfer, some are designed specifically for custody-transfer applications. Companies involved in developing these meters include KROHNE, GE Measurement & Control, Micro Motion, and Endress+Hauser.

Ultrasonic FlowmetersOne difference between custody-transfer and non-custody-transfer applications for ultrasonic flowmeters is that custody-transfer applications require three or more measurement paths within the meter. A path is the route traveled by an ultrasonic signal from one side of a pipe to the other and back. If the signal is “direct,” it is considered to be a one-chord path. If the signal bounces off a pipe wall or reflector, it is a two (or more)-chord path. One advantage of multiple paths is that the flowmeter measures flow velocity at more than one location in the pipe. Multiple paths and chords are also used for diagnostic purposes, and to reduce the need for flow conditioners.

Ultrasonic flowmeters are also used for custody transfer of petroleum liquids. There are many opportunities for custody transfer of petroleum liquids from the oil well through the refinery to the ultimate distribution point. Once oil is brought to the surface at a well, it is separated from any accompanying water and gas, and is often placed in a storage tank. In many cases it is taken from the storage tank to a refinery. The oil is typically subject to custody-transfer measurement as it leaves the storage tank and as it enters the refinery. A custody-transfer measurement also applies as it leaves the refinery and as it is distributed to its ultimate destination.

Ultrasonic flowmeters compete with turbine flowmeters for liquid custody transfer applications. Both types of meters can handle large line sizes. Ultrasonic meters have the advantage of having no moving parts and very little pressure drop. Turbine meters have spinning rotors that are subject to wear and do not perform well with high-viscosity liquids.

Differential Pressure (DP) Flowmeters

DP flowmeters require the use of a primary element to create a constriction in the flowstream. Examples include orifice plates, Venturi tubes, flow nozzles, and averaging Pitot tubes. They then use Bernoulli’s theorem to compute the flowrate. Much of the work done by the AGA on the use of DP flowmeters for custody-transfer applications involved the use of orifice plates.

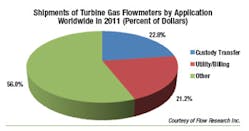

DP flowmeters got an early jump on the research into the use of flowmeters for custody-transfer applications. The AGA-1 report involving DP flowmeters was published in 1930. It wasn’t until 1981 that AGA-7, involving turbine meters, was published. During the 1990s, turbine flowmeters began to displace DP flowmeters, especially for gas applications. The main reasons were the higher accuracy of many turbine flowmeters, along with their greater rangeability.

In the 2000s, ultrasonic flowmeters began replacing both DP and turbine flowmeters, especially for gas applications. Like turbine meters, ultrasonic meters can handle most large line sizes, but they do not have moving parts. They also are highly accurate and reliable. One drawback to ultrasonic meters is that they are still seen by many as a new technology, while turbine is a more traditional and trusted technology. Another issue for ultrasonic flowmeters is their need for periodic recalibration. So far no one has come up with a broadly accepted formula for the recalibration period, though most companies recalibrate their ultrasonic meters sometime between every three to seven years.

DP flowmeters are not widely used for liquid custody-transfer applications. One reason is that accuracy requirements for custody transfer of petroleum liquids are higher than many DP flowmeters can achieve. Another reason is their limited rangeability. This is a disadvantage for applications with widely varying flowrates. Another reason is the difficulty in proving DP flowmeters, which rely on Bernoulli’s theorem for the flow calculation.

Turbine FlowmetersTurbine meter suppliers are also making technology improvements to make turbine meters more reliable. Many of these improvements involve making the moving parts more reliable. By making the ball bearings out of more durable material, such as ceramic and synthetic sapphire, turbine suppliers have been able to add significantly to the life of the bearings. This is important, since some customers select new-technology meters over turbine meters because turbine meters have moving parts. Other recently introduced improvements include bi-directional flow, self-lubrication, dual-rotor design, and significantly reduced pressure drop.

In addition to their use for custody transfer of gas, turbine meters are also used for custody transfer of petroleum liquids. Because of the presence of a rotor, turbine meters do better with lighter fluids than with highly viscous liquids. Turbine meters gained their widespread modern use during World War II, when they were used to measure fuel on military aircraft. Today they are used for custody transfer of crude oil and refined crude, and for loading rack service.

The Future of Custody Transfer

Custody-transfer applications exhibit the same trend evident elsewhere in the flowmeter world—the transition from traditional technology to new-technology flowmeters. Coriolis and ultrasonic flowmeters are displacing DP, turbine, and positive-displacement flowmeters for many applications. Even so, traditional meters have the advantage of installed base and are holding on to a large replacement market.

One advantage of new-technology meters is that more new product development is going into them than into traditional meters. There is no analogue among traditional meters to the development of large line-size Coriolis meters. Likewise, the development of multipath ultrasonic meters for both liquid and gas has resulted in highly accurate and reliable meters that can compete effectively with almost any type of traditional technology meter. Given the positive results, expect the emphasis on product development for new-technology flowmeters to continue for the foreseeable future.

Jesse Yoder, Ph.D., is president of Flow Research Inc. in Wakefield, Mass., a company he founded in 1998. He has 25 years of experience as an analyst and writer in process control. Dr. Yoder specializes in flowmeters and other field devices, including pressure and temperature products. Dr. Yoder can be reached at [email protected].