How much does a company spend each year on chemicals to ensure offshore oil production stays up and running? For most, chemical injection is an unavoidable cost of doing business. Since many of the chemicals injected are proprietary formulations and consequences of underinjection can be catastrophic, questioning the dollars spent can be challenging. But in today’s low oil-price environment, a critical examination of a chemical injection system and practices may yield tremendous operating expense (OPEX) savings.

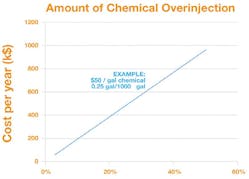

Chemical injection, as a cost of doing business, has a huge impact on a producer’s bottom line. Chemicals are a necessary expense. Without chemicals, problems can occur in the pipeline that can severely affect production. For example, scales and waxes could plug tubing indefinitely, or hydrates could block production, costing up to $1 million per day in shut-in production to dissociate. Without a corrosion inhibitor, a complete loss of well or infrastructure could occur over time. With such severe consequences, producers consistently inject more than the recommended quantity of chemical. A sampling of producers interviewed showed that chemicals such as demulsifiers are typically overinjected by up to 20 percent in attempts to ensure that an emulsion does not form and shut down production facilities. The annual cost of overinjection for a single chemical run at 20 percent excess could be as high as $400,000. Figure 1 details the additional OPEX impact of that single chemical cost as a percent of overinjection.

Consider a single offshore platform and the annual amount spent for injecting chemicals for six to eight wells. For a representative platform, four to six chemicals would be injected including scale, wax and corrosion inhibitor as well as monoethylene glycol or methanol for hydrate inhibition. In this case, one would inject more than 9,000 gallons (34,000 liters) of chemical per hour for eight wells. In total, this hypothetical platform could consume $175 million in annual operational costs just in chemical injection. And if all that chemical is overinjected at just 5 percent, that is potentially 4 million gallons (15 million liters), or $8.75 million worth, of wasted chemical injected in a single year for a single platform because of uncertainty in measurement and control. Chemical injection represents a tremendous cost, and in today’s environment, such an operational cost deserves more scrutiny.

In addition to poor chemical injection control, several other obstacles to good system operation hamper performance. Often the primary obstacle to system reliability is injection rate drift, either mechanically from the pump or from the valve that controls flow. Rate change can be caused by changes in back-pressure in the system or wear of their parts and seals. As temperatures change, chemical viscosity can change, resulting in a drift in the actual chemical injected versus indicated rate. One operator in the Gulf of Mexico noted that he or she needed to employ dedicated personnel just to monitor and adjust chemical injection rates every four hours. This presented a resource cost — not to mention additional bed space and health, safety and environment risks — that could be utilized elsewhere on the platform.

In the past, injection control devices have been maintenance-intensive, especially at startup and shutdown. Plugging issues with these devices, whether caused by chemical quality and precipitates or failed filters, added to the risk of underinjection of chemical and potential shutdowns. Another challenge noted for proper chemical monitoring and control is the wide turndown required over the life of the well. Many valves and mechanical flowmeters have limited turndowns that do not serve the range of expected flow rates over the life of the well, particularly as the asset declines or enters secondary or tertiary recovery. Lastly, space and weight for offshore systems are large considerations since they are at a premium for offshore platforms. Any reduction in equipment size and weight can result in significant upfront capital expenditure savings.

As a final complication, target reservoirs are deeper than ever, resulting in operating pressures for chemical injection equipment in excess of 10,000 psi (690 Bar), which limits the instrumentation and control options available.

The solution

Achieving significant savings in chemical injection requires confidence in the accuracy and reliability of chemical injection monitoring and control devices. With an accurate flow control device and a repeatable, accurate mass flowmeter, a closed loop can be created that constantly monitors and adjusts the chemical rate to ensure the right amount is injected at all times.

Recent advancements in Coriolis technology allow its use in emerging high-pressure chemical injection systems with operating pressures up to 15,000 psi (1,034 Bar).

So, what are the benefits of using a Coriolis meter with an accurate flow control valve compared to traditional mechanical meters and valves for chemical injection systems? First, Coriolis meters are extremely accurate and repeatable, with accuracies down to 0.1 percent of flow rate. This enables operators to account for all the chemicals used to a high level of confidence and can drastically reduce overdosing chemicals by ensuring the proper amount is being delivered every time. Next, unlike other meters such as positive displacement or turbine, Coriolis meters have no moving parts. This means that no parts are present that will wear out over time and need replacing. The lack of moving parts also greatly reduces the need to stock spare equipment for maintenance, which helps ensure that downtime is reduced and can drastically lower operating costs. Additionally, Coriolis mass flowmeters do not require straight runs to condition the flow profile, which provides a smaller footprint for space and weight savings on the platform.

Also, Coriolis meters are true mass meters. Mass meters measure the amount of flow, regardless of changes in fluid properties such as density and viscosity. This is important because it allows a single meter to be used to measure multiple chemicals. Conversely, volumetric meters have errors associated with changing fluid characteristics like pressure or temperature. Also, some meters need to be calibrated directly to the fluid being measured in the process to meet their stated accuracies. This is not true for a Coriolis flowmeter. Coriolis meters provide accurate measurement, even if the fluid characteristics change, providing certainty that the flow rate is correct.

Additionally, Coriolis meters are multivariable devices capable of measuring density and temperature. Density is important because it is a great quality control measurement that can monitor changes in composition of the chemicals being injected. The density output can be used to monitor product density or concentration measurement. Concentration limits can be set for fluids and to provide indication and alarm if the chemical concentration or fluid properties change over time. This ensures the chemical is within specification and that the correct chemical is injected downhole. Additionally, the density measurement can be used for interface detection.

Furthermore, advances in diagnostics allow for better maintenance practices. For example, some meters are offered with diagnostics. Coriolis meters have no moving parts and are not expected to degrade over time, but many technicians have entrenched work practices that may have them question the integrity of the instrumentation. Others may have internal procedures in place to calibrate equipment at a specific time interval. One verification tool can be run remotely and automatically or by a touch of a button to provide confidence that the meter is in its original factory condition.

The tool works by using an established baseline that is programmed into each new meter from the factory. This baseline is stored in the electronics and can be referenced at any time in the field. Once in the field, a user can run a test to compare its present value to its original baseline and see if any changes have taken place in the meter. This diagnostic can extend or eliminate calibration intervals and give confidence that the meter operates accurately. The complete meter is checked, including sensor (coils, resistance thermometer and tube integrity) and transmitter (zero, configuration and alarms).

Finally, the advanced Coriolis meter can be combined with an accurate chemical injection flow control valve that utilizes an integrated, microprocessor-based proportional-integral-derivative controller that brings precise, algorithmic control to chemical injection systems. This technology provides responsive control that allows the valve to adapt to an ever-changing system and accuracy to 0.1 percent, which reduces downtime and maintenance associated with clogging.

Through use of a flow control valve and Coriolis mass meter, the space and weight of the chemical injection system can be dramatically reduced. Figure 2 demonstrates how a single tank and pump per chemical can be used to reliably supply each of the wells on a platform. This significantly reduces maintenance requirements with fewer pumps and filters to maintain while reliably and accurately delivering the exact amount of chemical that each well requires.

Summary

Traditional flow control methods have large amounts of variation, poor repeatability and injection rate drift that drive operators to overinject chemical to ensure protection of their assets while incurring significant OPEX in excess chemical. Variation in flow can be a result of the device design that does not account for variation in the process parameters. Precision chemical injection flow control that retains consistency regardless of downstream pressure fluctuations, changes in chemical properties or other changing conditions, is necessary to bring injection rates closer to the required rate. Coriolis and flow control technology advancements enable more reliable operation of the chemical injection system, which reduces maintenance and overinjection while keeping production up and running with a smaller footprint.

Timothy Drost is a global product manager for Emerson Automation Solutions. He has been with the company for more than 13 years. He holds an MBA and Bachelor of Science in mechanical engineering from the University of Colorado, Boulder.

Wendell Love is an oil and gas industry manager for Emerson Automation Solutions. His background includes 10 years of oil and gas experience with downhole tools, frac equipment and production systems. Love joined Emerson in 2013 to expand pressure control product lines. He has a Bachelor of Science in mechanical engineering from Texas Tech and an MBA from Southern Methodist University.

Laura Schafer is vice president of oil and gas for Emerson Flow. With more than 15 years of oil and gas experience, she joined Emerson in 2012 with a focus on extending flow measurement applications in oil and gas. Schafer holds Bachelor of Science and Master of Science degrees in chemical engineering from the Colorado School of Mines.