Does the term “centrifugal pump” bring to mind a floor-mounted ANSI dimensional pump coupled to a standard alternate current motor through a gearbox to achieve the proper flow for the application?

These pumps employ an internal impeller using centrifugal force to “throw” material against the outer wall of the pump to force fluid out of the pump. This style of centrifugal pump is universally used in the food and beverage industry to transfer low-viscosity fluids within the plant. It is flexible since it can deliver flow rates of up to thousands of gallons, can often accommodate clean-in-place (CIP) procedures, and is an affordable option for the application.

The popular standard centrifugal pump is a great choice for low-viscosity transfer within a food and beverage facility. However, a weakness is present in the beginning of the production line. This application is ingredient transfer, which is impacted by packaging and delivering ingredients to factories. Most liquid ingredients are packaged in either drums (55-gallon or other configurations) or intermediate bulk containers (IBC) of 300 gallons or more.

Often these containers do not have bottom outlets and require the pump or suction line to be inserted into the container through a top-mounted bunghole or larger threaded opening. Standard centrifugal pumps must be placed on the floor next to the container with a suction line connected to the pump inlet and inserted into the top of the container. The issue with this installation is that standard centrifugal pumps cannot draw a large suction and would not be able to siphon this material from the drum with any success, which would require the pump to be manually primed each time a user needs to empty a new drum or tote of material.

Solution: Sanitary drum pumps

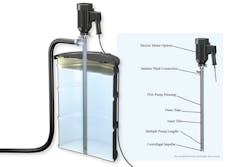

The solution to this common problem is sanitary centrifugal drum pumps. These pumps employ a similar design as a standard centrifugal with an impeller that throws material against the outer pump wall to push it through the outlet. The main difference between the pumps is how the drum pump version installs the impeller at the bottom of a pump tube that is inserted into the fluid container and sits at the bottom of the container. Having an impeller at the bottom of the tube — and the bottom of the fluid — within the container means the pump no longer must draw suction to load the material into the pump, which is a benefit. This is the case because the gravity and pressure of the fluid in the container will push the fluid into the pump and allow the impeller to be pressure-fed, which prevents the opportunity to run dry.

While drum pumps offer a benefit on the actual pump operation, when it comes to ingredient transfer they have other advantageous design aspects. The pump and drop tube are integral to one another and are portable and lightweight for end users. This is particularly critical when discussing ingredient transfer since most users move the pump from drum to drum or container to container once they complete the evacuation of the first container. The lightweight and portable design makes it ergonomically safe and easy for operators to move the pumps around.

Sanitary drum pumps also allow for variable speed operation without the requirements for a variable frequency drive, which is needed to adjust speed on most standard centrifugal pumps. This makes installation significantly easier since often, no wiring is required by the user. All he or she needs is a 110-volt (V) or 230V electrical outlet.

Specifying a drum pump

When selecting a drum pump, be aware of a few items to properly select the correct pump for the application.

Length — The first item to consider when selecting a drum pump is the pump tube length. Since the drums or IBC containers can come in various sizes, it is important to know the overall height of the fluid container to ensure the pump is long enough to reach the bottom of the container. If the pump tube is too short for the container, a layer of material will be left in the bottom of the container, which the pump will not be able to reach to evacuate.

Material of construction — Most food, beverage and personal care facilities have similar requirements, but it is important to know what kind of materials will be run through the pump – including the product in the containers being evacuated and the chemicals used to clean it – to ensure the pump chosen is built from the proper materials. Food plants may just require stainless steel while personal care facilities may require 316L stainless steel for their applications. Aside from just the pump tube itself, users should ensure any seals within the pump meet the compatibility of what they pump. Pumps are often available with Buna or polytetrafluoroethylene (PTFE) seals/packings with PTFE being the most chemically compatible option.

The pump impeller is important to check out as well. Plastic and stainless steel impellers are available on the market, with stainless steel often the most compatible with food materials and cleaning chemicals. Stainless steel impellers are advantageous for companies that employ metal detectors to catch contaminants within the end food product because a stainless steel impeller or piece can be caught, while a plastic impeller will be missed by a metal detector. Stainless impellers also offer greater abrasion resistance and longer life when compared to plastic impellers.

Head pressure required — It is important to know how far to pump the material and how much pressure is required at the pump outlet. If pumping long distance or with smaller fluid lines, more pressure may be required than a centrifugal pump can produce. Different impellers allow for higher pressure. The standard impeller design in the industry typically generates up to +/- 40 psi and the high-pressure impeller versions can generate twice that with +/- 80 psi. For anything that requires pressure above that, users should consider a piston pump or progressive cavity drum pump.

Material being evacuated — Not only is it important to look at the pump, but surveying the materials to use it on will help determine a good fit. Typically centrifugal drum pumps can transfer materials with viscosities up to 1,000 centipoise (cps) with wiggle room to go higher depending on how far the product is being transferred. If users try to use the pump on a product thicker than 1,000 cps, they may have issues with cavitation and premature pump wear.

It also is important to make sure the material being transferred does not contain large particles. These large particles can clog the pump or be cut or damaged by the pump during operation. Shear sensitive fluids can also have issues with centrifugal drum pumps since the centrifugal impeller can be shearing or froth fluids.

Motor and power – The last step in pump selection is the motor. Select a motor that can operate on power that is readily available throughout the facility. In the U.S., that is typically the 110V power source, but in Europe or other countries, a 230V motor may be the best option.

Depending on the environment and facility cleaning procedures, consider whether the installation requires a washdown-rated motor.

The final requirement to be aware of is if the pump will be installed in a hazardous location and require an approved motor. This typically applies to personal care facilities because of the amount of alcohols and solvents used during the production process.

Typical applications

Applications for centrifugal drums pumps can vary widely throughout the industry but are focused on low-viscosity fluids that are easily pourable out of a container. They can include, but are not limited to: syrups, salad dressings, juices, concentrates, flavored waters, beer, wine, other beverages, low-viscosity lotions, cosmetic fragrances and flavorings. It is important to note that all applications pump materials that are typically under 1,000 cps fluid viscosity. When utilized in conjunction with the above requirements for specifying pumps, centrifugal drum pumps can be valuable additions to any food processing facility.

Jeff Shaffer is worldwide product manager for Graco Inc. in the Process Division. He is responsible for Graco’s sanitary equipment and electric process pumps. Shaffer may be reached at [email protected] or 612-379-3702.