Assuring safe, optimal operative conditions for compressors is one of the primary goals for process plants. During the last decades, the approach to plant machinery maintenance changed considerably — from an initial approach with repair interventions after failures (corrective maintenance) to the preventive approach with part replacement at fixed work hours. More recent developments have led the predictive approach based on mechanical parameter observation.

Today, predictive techniques commonly implemented are connected to the reading of vibrational parameters and, in general, to machine mechanical indicators (mainly bearing vibrations and temperatures), where the observation of vibrations and temperatures provides a way to avoid dangerous operative conditions, triggering alarms and trips.

A better look at machine condition can be provided by the evaluation of machine performance. In many cases, machinery problems appear progressively and introduce losses in performance and efficiency, even without dominant presence of mechanical indicators. Also, in some cases, mechanical damages may present a cumulative behavior, such as the case of compressor surge, and silently and progressively cause an increase of damages inside the machine. In this scenario, the performance analysis may be helpful. These considerations highlight the importance of understanding how the machine is performing beyond the strict check of mechanical indicators limits. In this approach, the machine capability to deliver expected performance provides a root signal of machine health status, and a lack of performance is seen as the earliest external indicator of a problem on the machine.

Evaluation of machine performance introduces the requirement for a machine performance model used as a reference baseline for performance evaluation. This approach paradigm is sometimes referred to as digital twin. The performance analysis is a quantitative approach that could be used as a base for new machinery maintenance support systems.

In many cases, machinery problems appear progressively and introduce losses in performance and efficiency, even without dominant presence of mechanical indicators.

For compressors, the prediction of expected performance requires a sophisticated approach involving an aero-mechanical machine model and application of gas thermodynamic theories and, consequently, the use of adequate calculation tools.

Next-generation monitoring software: The model-based proactive approach

Next-generation machinery monitoring software should embed the capability to dynamically evaluate the machine performance according to effective operative conditions, where "dynamically" indicates only the capability to adjust the performance prediction to actual operative condition in real time, accommodating process parameter variations.

Also, these systems should be able to tentatively identify possible problems and allow timely intervention scheduling. This is currently known as a proactive approach. Current personal computers offer all the computational capability required for implementation of accurate machine model-based performance monitoring methods, bringing the traditional predictive systems into the proactive maintenance dimension. Advanced diagnostic capabilities should arise from the coupling of machine performance analysis capability with the traditional predictive methods based on analysis of mechanical parameters (vibrational, thermal and tribological), thus it is not replacing but embedding and extending the previous system capabilities.

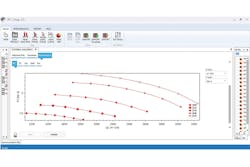

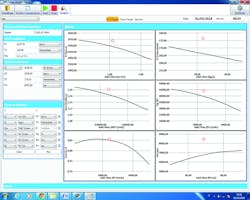

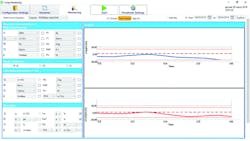

Figures 1–5 show screenshots of the Cmap software for the prediction of centrifugal compressor performance in off-design conditions.

Performance-based diagnostic method and definitions

At the core of a performance monitoring system should be the capability to compare the actual performance to a valid reference value. In order to be significant, this reference value should represent the optimal machine performance, i.e., the performance of a new machine or a machine restored to like-new conditions.

Under this hypothesis, design performance, or as-tested performance, provided by the compressor OEM, may be used as a valid reference point. Here, more details become necessary. In fact, while the measurement of actual performances is straightforward, the evaluation of the reference performance may be more complex since these need to be adjusted to actual operative conditions. Specifically, for centrifugal compressors, the reference (design/as-tested) performance needs to be adjusted to actual suction pressure, suction temperature and actual gas mix composition. This adjustment is necessary to make the reference performance homogeneous to the measured ones, allowing a valid and meaningful comparison. This adjustment step is not trivial because it requires an accurate numerical evaluation. Many physical aspects of the compression process — from the compressor aero-mechanical behavior to the gas thermodynamics — need to be considered and, due to its quantitative and numerical nature, this method requires the availability of adequate computing tools.

For centrifugal compressors, the reference (design/as-tested) performance needs to be adjusted to actual suction pressure, suction temperature and actual gas mix composition.

Today, the diffusion of powerful desktop computational capabilities and the market availability of machinery performance prediction software such as Cmap (software for centrifugal compressors performance), these complex machine modeling capabilities are fully available to the user and allow implementation of detail diagnostic strategies based on machine performance analysis.

Model-based performance: The productive approach

The concept of model-based performance evaluation within machinery maintenance also marks an irreversible change from qualitative evaluation to numerical. This new approach can align maintenance and operations departments to the same page with engineering, sharing methods and tools. The same software such as Cmap may be used in the design stage for evaluation of performance in different operative cases to the operational stage for current performance evaluation, allowing the analysts to refer to a shared database and analysis method throughout the life cycle. This process of integration at plant level is sometimes called performance productive maintenance. It integrates the machine maintenance task within the scenario of the entire plant productiveness.

For centrifugal compressors, the starting point of the method is the availability of reliable reference performance curves along with relevant gas mix composition and thermodynamic conditions (pressure and temperature). With this input data available, it is possible to implement monitoring software that is able to continuously observe the compressor operative parameters and compare these with the expected ones in the actual operative condition.

This kind of monitoring software, based on machine performance model software (powered by Cmap), will perform all complex calculations, fully automated, and produce the expected compressor performances for inlet pressures, inlet temperatures and gas mix compositions different for design/reference ones.

The basic requirement for the implementation of such method is the availability of compressor reference performance with relative reference conditions (for example, compressor OEM as-tested performance data and relative test conditions) and operative parameter readings from the field. In many cases, this data is already available at plant DCS level and can be retrieved and used for performance calculation. (See Figure 2.)

Figure 2. Monitoring software field data connection

Within the IPC Monitoring software, the availability of field data is granted through a connection to a process operative parameter database, usually available at DCS level.

The monitoring graphical interface allows retrieval of all necessary field parameters and sets up a connection with the source database quickly and intuitively. Compressor configuration is provided through a link to the Cmap machine database where compressor reference performance (for example, OEM design) is stored.

Once the connections are saved, the system is ready to run autonomously and provide continuous detail performance evaluation.

With Cmap capability to model the centrifugal compressor, it is possible to obtain a valid comparison in terms of evaluation of compressor performance in actual condition (as-expected performance). This method is also compliant to the ASME PTC10 (Performance Test Code on Compressors and Exhausters) standard.

System configuration parameters are the compressor map in reference condition at variable speed, the inlet reference condition, i.e., inlet pressure, inlet temperature and gas mix composition, the selected EOS for gas properties calculation.

Measured parameters (actual) used as inputs are inlet and discharge parameters (pressures, temperatures and flow), running speed and gas mix composition.

As output, the software will provide the expected performance (pressures, temperatures, head, efficiency, etc.), the XY graphs of compressor performance curve at the actual speed and inlet conditions, the time trends for all performance parameters and the time trends for all deviations.

Figure 3 shows the graphical window for visualization of XY graphs for actual performance. The red dot represents the actual operative performance point. The actual point is superimposed to reference performance curves adjusted to actual operative conditions.

Figure 3. XY graphs for actual performance

Once performance values are obtained, it is possible to compare the actual values to the expected ones. The differences between these values are indicators of how much the compressor behavior deviates from the normal/optimal behavior. These indicators are referred to as performance deviations.

Performance monitoring

As a corollary of previous definitions, we can define a value as "normal" at a certain time when its deviation is zero. Consequently, zero deviation represents an operative status where the machine is operating as expected, according to reference performance.

If the reference performance is relative to an optimal (as-new) machine condition, then the deviation gives a measure of how far the machine behavior is from the optimal condition. Interestingly, these parameters may also be trended in time. The change in time of a deviation parameter should represent a measure of how quickly the observed performance moves away from its normal value. When a performance deviation becomes irreversible in time, it is possible to say that the machine suffered a performance degradation.

A stable degradation may be read as a sign of a noncritical defect, compatible with machine operations and affecting mainly performances. Degradations increasing in time may be understood as a sign of development of a defect, and they will lead to critical events if not interrupted.

Figure 4. Time trends

Time trends of performance deviations, deviation rates and degradations can provide a powerful indication of machine health status and may be coupled with mechanical indicators, with specific diagnostic logics to address possible failure causes.

An application has been implemented in IPC Monitoring software (see Figure 5). This quantitative performance evaluation approach can allow for implementation of maintenance strategies, optimizing schedules of interventions for max production and minimal costs.

Figure 5. Time trends of performance deviations

Conclusion

The methods proposed and described here can obtain a quantitative comparison of actual (off-design) compressor performances to the expected ones.

The prediction of compressor performances is obtained without approximation and using all recent theories for compressor and real gas modeling, even for complex gas mixtures. Results are proven to be accurate even at high pressures, where the ideal gas theory commonly used introduces considerable errors. Also, the method has provided accurate results on almost all compressors in the market.

Figure 6. Monitoring system layout

The method can provide useful diagnostic indications on the health of the compressor based on the capability to analyze the performances and efficiency of the machine in a simple, immediate way. This capability may be useful in supporting decisions and planning of predictive maintenance and activities.

On existing machinery, the described methods provided a more accurate surveillance of the machines and could detect failure indicators earlier than traditional methods. The availability of a real-time machine model continuously predicting the expected performance has also been used to detect possible anomalies in instrumentation reading, especially concerning the measurement of suction flow, which may be affected by problems and introduce consequent errors. The capability of the presented method has been used to support the optimization of overall compression plant control systems and provide financial and environmental-related benefits.

Massimiliano Di Febo is operation manager at IPC. He can be reached at [email protected].

Pasquale Paganini is a technical manager at IPC. He can be reached at [email protected]. For more information, visit ipc-eng.com or compressormap.com.