SimuTech Group, the largest full service North American ANSYS channel partner, recently completed a series of sophisticated analyses of wastewater flow at the Southerly Wastewater Treatment Plant that serves the greater Cleveland, Ohio area. SimuTech was contracted by Burgess & Niple, a civil engineering firm, to help determine the impact and potential improvement of proposed changes to the plant’s grit removal system.

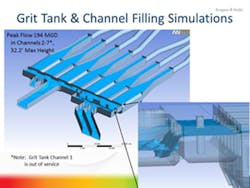

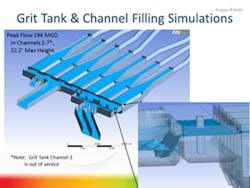

SimuTech consulting engineers Michael Showalter and Mark Goodin performed computational fluid dynamic (CFD) simulations using ANSYS CFX software. The project was comprised of three phases. Showalter said, “The first phase of the CFD analysis for the Southerly project was to model the water flow through the grit tanks under both nominal and peak flow conditions. The objective of this analysis was to determine the water level in the grit tanks for both flow conditions with the proposed new flow baffling. It was very important to ensure that inclusion of the flow baffles did not reduce the maximum water capacity of the tanks.”

The second phase involved modeling wastewater flow through a single grit tank with proposed air injection nozzles and flow baffles installed. The CFD model was used to determine the required airflow from the nozzles to reach the desired rotational flow in the grit tank. The simulations also revealed that one of the proposed flow baffles actually impeded the rotational flow and could be removed resulting in a $70,000 cost savings.

The third phase of the CFD analysis used the air injection conditions determined from phase two and released small and large grit particles into the wastewater flow upstream of the grit tank. The CFD simulation tracked the path of these particles as they flowed through the grit tank system and predicted the removal rates of various sized particles. The conclusion was that the predicted removal rates met the design goals.

As a result of using CFD technology, the Burgess & Niple team realized a $70,000 savings to the Southerly project. Carl Seifried, P.E., Burgess & Niple Project Manager, noted, “The simulations showed that we could eliminate one of the originally proposed flow baffles. The ability to visualize ‘what-if’ scenarios before constructing and testing the grit tank modifications saved both time and considerable expenses.”