This might sound obvious, but a seal designer may have different operating condition concerns than the user. It happens too often that a particular parameter is viewed and encouraged as the most important, yet it is actually the combination of two or three parameters that presents the real challenges. The following application details should be shared with seal designers.

Type of movement(s)

Linear (reciprocating back and forward) motion is generally assumed to be reasonably easy, but very long strokes or short, frequent strokes can lead to the sealing contact area becoming starved of lubrication, leading to excessive seal or counter-surface wear.

Rotating (spinning shaft or bore) motion presents heat buildup issues as every part of the circumference passes the same part of the seal lip every rotation. The seal’s ability to seal but create low friction is vital in rotating applications. The addition of media pressure increases the seal lip force, which increases heat buildup. The effect of pressure x velocity can be calculated with an online PV calculator.1 From the equipment designer viewpoint, heat dissipation away from the seal contact area should always be incorporated to minimize any heat gradient.

Material tensile test

Oscillation (rotating less than a full rotation backward and forward) presents the challenge of allowing immediate movement in the direction of rotation, yet requires an immediate seal even when changing the direction of movement or pressure.

Mixed motion (helical movement or switching from reciprocating to rotation and back) requires the seal to not only handle the challenges listed above, but it must also function well during the transition from one motion type to another.

Static (no relative movement between the two surfaces being sealed). In many food applications, no voids can be present because they may promote bacteria growth. Under these circumstances, special seals designed to bulge can eliminate the need for welding joints.

Autoclavable OD labyrinth seals

Operating parameters

Share pressure, normal speed and temperature at this pressure with the designer. Unfortunately it is common to list the worst operating conditions that may occur only in extreme circumstances for short durations. If the normal operating conditions are given as well as the maximums, a design can be produced to operate best under these conditions but also able to withstand short excursions to a maximum condition.

Maximum pressure, speed and temperature

These parameters can only be viewed against the associated parameters experienced. For instance, maximum pressure can only be viewed through the prism of the accompanying speed and temperature at this pressure.

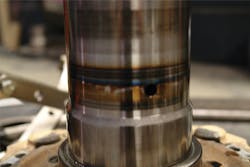

Excessive heat under seal lip

Seal fitment and machine assembly

Many seals have fitment issues that can mostly be overcome if addressed at the initial design stage, but can present insurmountable obstacles at later stages. Many seals require open housings and will be damaged or are impossible to fit in closed glands. The direction of insertion of the seal into the housing and shaft through the seal can also present real challenges. It is strongly recommended that equipment designers provide seal manufacturers with a general assembly drawing as early as possible in the process so this issue is overcome or minimized. Many reputable seal manufacturers will either design or help design fitment bullets and tools to ensure correct, damage-free seal fitment. Remember that the smaller the diameter, the more difficult stretching or compressing will become.

Housing and counter-surface materials

The food industry uses many housing, piston and shaft materials that present challenges to seal designers. Contact surface materials can drastically reduce the possible seal materials available to the designer and should be advised as soon as possible. A perfect example is polytetrafluoroethylene (PTFE) materials that need to be passivated when used with stainless steels or the stainless surface could pit.

PTFE seals

Media to be sealed

This is especially important if the media will change in operation or if the equipment being designed is to be suitable for a wide range of media. Media are large driving factors in seal design and seal material selection. Sometimes it is simply a necessity to have more than one sealing option depending on the media. If the media are a mixture, many companies will conduct media compatibility studies on the mixture if it is provided. Also bear in mind that if an additive package is added to a fluid, the fluid tested must contain the additive package. For example, one compatibility test was conducted on pure water and the same water but with the additive package, and over six months the variation of results grew larger and larger.

Cleaning method

How the equipment will be cleaned in service can have a huge effect on seal design. It is not uncommon to discover that the best seal design and material for the application is totally unsuitable for the intended cleaning method. As soon as this is discovered, it should be communicated to the seal designer to ensure the application, media and cleaning method to be deployed are all considered together. Based on the path of cleaning fluid or cleaning method, seal designers can consider minimizing crevices or aid effective clean-in-place procedures. Regardless of seal material suitability for sterilization-in-place, testing should be conducted by the user with the seal fitted and subjected to multiple autoclave cycles before assessing seal performance. Autoclaving can produce an adhesion between seal and counter-surfaces (dependent on counter-surface materials) that can sometimes be detrimental to seal performance.

Left: Piston with different seals for different media; Right: Multi-lip, V-spring seal

Other considerations

- Stationary stability of the media being sealed should also be considered. In many cases, foodstuffs can solidify or crystalize when stationary for a period of time. If this circumstance can happen, make the seal designer aware. Solids, especially sugars, can have a detrimental effect on many seal materials, and designs must do as much as possible to mitigate those effects.

- Certification of the seal material should also be communicated to the seal designer since not all "food-quality" materials are Food and Drug Administration-compliant. If equipment will be shipped to the European Union, please check that materials are REACH-compliant, meet European Commission food regulations and Good Working Practices, and are free of animal-derived products.

With the above information in hand, a seal designer can recommend a suitable seal that will provide the longest possible service life.

Reference

Derek Duncan is technical director for American High Performance Seals Inc. He has designed seals for the food industry in Europe and the U.S. for more than 35 years.