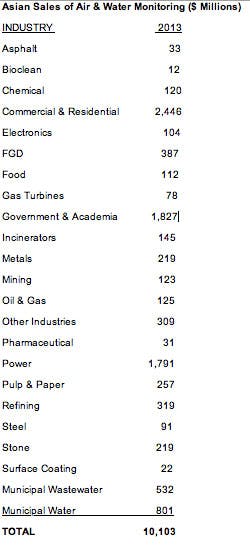

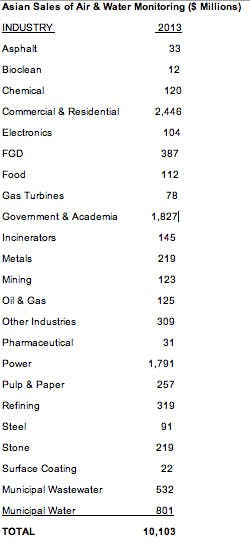

Air and water monitoring revenues include sales of laboratory, continuous and portable instruments, and systems. These include process gases and liquids, as well as exhaust gases and liquid waste streams. The values reported include physical properties, such as flow and temperature, and chemical constituents, such as ammonia or cadmium.

Power is the largest industrial user of air and water monitoring equipment. McIvaine says these plants extract more water than any other industry and discharge more gases to the atmosphere than all the other industries combined.

Process gas instrumentation includes measurement of oxygen, carbon monoxide, temperature and flow. It also includes related measurements such as fuel flow.

Laboratory equipment is also included. Often a solid, e.g. filter catch, is measured to determine the constituents in the air or gas. Where the analysis of the raw material is necessary for pollution control purposes, this is also included. Many regulations affecting pollution control in coal-fired power plants require measuring the sulfur or mercury in the coal being burned. In the cement industry, the metals are measured in the limestone feed as well as in the stack gas.

The power industry in Asia is investing more than the rest of the world combined in boosting electrical capacity. Asia also leads in the expansion of municipal water and wastewater. McIlvaine reports municipalities in Asia will spend $1.2 billion for air and water instrumentation next year. Most will be for water quality. However, odor control is a big problem and will require a significant investment in portable test equipment.

McIlvaine says the trend is away from laboratory testing and toward continuous monitoring. Municipalities presently have large investments in laboratories and considerable operating expense devoted to periodic sampling. This will be sharply reduced as these plants invest in systems that will continuously monitor and control the processes.

For more information on Air & Water Pollution Monitoring World Markets click here.