MEASUREMENT

ST100 Thermal Mass Air/Gas Flowmeter WHAT’S INNOVATIVE?

FCI’s ST100 Series is a feature-rich and adaptable thermal mass gas flowmeter solution for industrial process applications, providing such key features as: a unique digital/graphical display for continuous viewing of all measurement data; 4-20mA, HART 7, Foundation Fieldbus, Profibus, and Modbus outputs; exclusive triple variable measurement of flow, temperature and pressure; onboard data logger stores five calibrations; and VeriCal in-situ calibration verification.

The innovation and improvements of the FPI Mag are driven by the features mentioned hereafter.

Ease of hot-tap installation: The FPI Mag flowmeter installs without interrupting service, dewatering lines, cutting pipe, or welding flanges. The easy hot-tap installation makes the FPI Mag particularly cost-effective for retrofit applications, replacing flowmeters, or in sites never metered before. Installation costs for medium and large lines are reduced more than 45 percent by eliminating the need for heavy equipment or extensive manpower.

Multi-electrodes deliver accurate full profile: The Full Profile Insertion Mag’s unique operating principle delivers accuracy unmatched by other insertion magmeters and rivals the performance of a full-bore magmeter. Continuous measurement across the entire flow profile compensates for variable flow profiles, including swirls and turbulent ?conditions.

Robust construction for operational longevity: The sensor body is made from heavy-duty 316 stainless steel for maximum structural integrity. An NSF-certified 3M fusion-bonded epoxy coating ensures superior long-term operation.

Virtually no recalibration or maintenance: The FPI Mag’s highly stable flow sensor comes pre-calibrated from McCrometer’s NIST-traceable calibration lab and requires no recalibration.

WHAT’S INNOVATIVE?

The Sage Prism is a portable battery-operated thermal mass flowmeter that logs 3,800 points of gas flow during 10 hours of operation. The data-logging flowmeter features 16 selectable gas calibration ranges and includes free software.

Coriolis mass flow technology has historically been contained to traditional four-wire power/signal methodologies due to the need to power the sensor, amplifier, transmitter, and outputs. The Promass E 200 is innovative in that it maintains the highest levels of Coriolis accuracy and reliability while operating under a two-wire, loop-powered concept, which significantly limits the available power to the Coriolis meter.

In addition to the Adaptive Power Techniques used by the Promass E 200, this product line has set a standard for commonality across the Endress+Hauser flow and level product lines. The two-wire product lines from E+H will now share common Human Machine Interface, spare parts, and electronics modules. The new HistoROM capability provides an onboard nonvolatile device memory that enables data management and automatic data backup for device configuration. The HistoROM offers extended functions for an embedded event logbook, including the data logging for over 1,000 points.

WHAT’S INNOVATIVE

Endress+Hauser’s Promass E 200 is a two-wire 4-20 mA HART, loop-powered Coriolis flowmeter that uses patented Adaptive Power Techniques to provide continuous, accurate and reliable mass flow and density measurements without the need for converters, custom power supplies, or barriers.

CONTROL

FUTUR OMEGA-Series AODD Pumps By employing PTFE or stainless steel for all outside housing parts and nonwetted parts, safety is improved because the pumps are resistant to acid mists and acid leaking. The optimized PTFE material of the diaphragm has a doubled-strength against flexural stress compared to standard PTFE, helping to reduce maintenance and production costs.

Solid housing parts are machined on modern CNC-machines, which enable the smallest possible tolerances. The solid housings absorb mechanical vibrations and noise level.

WHAT’S INNOVATIVE?

The FUTUR OMEGA-Series, with its solid and complete PTFE or stainless steel design, using the newest generation of PTFE compounds and diaphragm geometry, has been developed for high-end semiconductor applications with double the lifetime of most AODD pumps for similar applications.

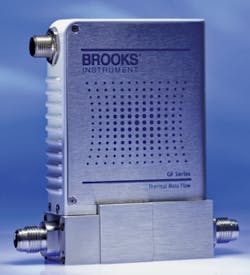

At the heart of the GF Series is Brooks MultiFlo, a patented technology that allows users to select new gas calibrations and full-scale ranges without the trouble and cost of removing the mass flow controller from the gas line. A major advancement over traditional single-point gas conversion factors, MultiFlo mass flow controllers typically deliver a three times improvement in accuracy through advanced gas modeling and compensation for non-ideal/non-linear gases.

WHAT’S INNOVATIVE?

The GF Series’ MultiFlo gas and range configurability can be reconfigured for new gas calibrations and full-scale ranges without the time and cost of removing the device from the gas line.

The transducers work either together or independently to detect pulse interference, allowing twice the application security. Hawk’s transducers do not require contact with the product. The switch requires a simple one-minute setup and allows for remote test function.

The acoustic switch is designed for continuous operation in dusty, wet environments where other technologies fail. The transducers are used for blocked-chute detection in wet or dry environments. They are self-cleaning and are compatible with communications, such as Modbus, HART, Profibus DP, and DeviceNet.

WHAT’S INNOVATIVE?

The Hawk Acoustic Wave Switch uses high-power/low-frequency transducers, which are self-cleaning. The power of each pulse (pressure wave) blows the water, moisture and buildup off the face of the diaphragm. The Acoustic Switch is designed for continuous operation in dusty, wet environments where other technologies fail.

The unit is available with a Pilot Module, which is a front-mounted or hand-held control device that allows users to employ Sierra’s Dial-A-Gas technology to change flowrate, modify engineering units, or reconfigure the instrument. With the Pilot Module, the user can set zero, span, and full scale for each of 10 different gases independently to accommodate unexpected application or system-design changes.

Sierra’s new Smart Trak 2 controller utilizes an inert carbon-reinforced polyimide valve seat and a unique notched (patent-pending) design. The unit can precisely control flows at pressures up to 5,000 PSIG (333 barg) over a wide range of flows from 100 SCCM to 50 SLPM, with leak-by of less than 0.08 percent. This represents an order of magnitude in performance over equivalent metal-seat controllers.

With the addition of Sierra’s Compod technology, the Smart Trak 2 transforms into a fully network-enabled Modbus RTU device, complete with integrated programmable relays and analog inputs.

WHAT’S INNOVATIVE?

Utilizing a unique (patent-pending) valve design, Sierra’s high-pressure unit will precisely control gas mass flowrate at pressures up to 5000 PSIG (333 BARG) over a wide range of 100 sccm to 50 slpm, with leak-by of less than 0.08 percent. This represents an order of magnitude performance improvement over equivalent metal-seat controllers.

This adaptive technology determines the optimal diaphragm rod velocity and relays the information to an air-distribution valve at the air inlet location of the pump. The valve acts as a gated air-management system, allowing only enough air to enter each inner-pump chamber. Diaphragms perform at their optimal operating point, with less air consumption. As the pump experiences air inlet fluctuations or other changes that affect air flow, the system adapts to optimize the pump’s performance.

AirVantage utilizes existing air flow to provide its own electricity and power to the device. This eliminates the need for batteries or hard wiring.

WHAT’S INNOVATIVE?

AirVantage significantly reduces air consumption over conventional AODD pumps. Beta tests and field trials have shown that AirVantage provides up to 50 percent energy savings compared to traditional AODD pumps.

Turcon PTFE-Based Sealing Material

Testing has shown that Turcon M12 is resistant to virtually all media, including a broad range of lubricants, and has outstanding wear-resistance and friction characteristics. The cost-effective material also provides customers with extended seal life, as well as a wide operating window in terms of temperature, pressure and velocity.

Key to achieving maximum seal life is to make sure that sealing compounds match up to application parameters. If a material can stand up to a greater variety of conditions, this makes the compound more versatile.

Considerable R&D time was devoted to develop a PTFE-based material that is compatible with a broad range of lubricants. It also had to demonstrate minimal wear with excellent friction characteristics at extreme temperatures, high pressures, and rapid velocities.

A specification was put together for a “dream” PTFE material, one that could fit virtually all hydraulic applications. This, according to Trelleborg, was achieved with Turcon M12.

WHAT’S INNOVATIVE?

Turcon M12 from Trelleborg Sealing Solutions is a polytetrafluoroethylene (PTFE)-based sealing material whose performance is unrivaled in key hydraulic sealing characteristics, such as friction, wear and high-pressure operation. Extensive testing showed that Turcon M12 is resistant to virtually all media, including a broad range of lubricants and has outstanding wear resistance and friction characteristics.