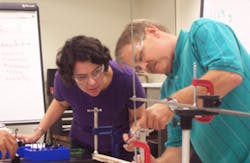

(Photo courtesy of UTeachEngineering, The Board of Regents of the University of Texas System)

Five years ago, some high schools in Texas began offering a year-long course in engineering to meet a state requirement of a fourth year of science for secondary school students. However, between 1995 and 2010, only 44 Texas high-school teachers became certified in engineering, according to a report by the National Science Foundation. With the potential for 10,000 to 20,000 students enrolling in engineering each year to satisfy graduation requirements, UT Austin projected that the state could need as many as 500 engineering teachers.

Aware of the great need, UT Austin's David Allen, a chemical engineering professor, teamed with colleague Richard Crawford, a mechanical engineering professor, and Cheryl Farmer, a program manager. Together with colleagues from UT Austin's Colleges of Natural Sciences and Education and the Austin Independent School District, they applied for an NSF grant to fund the creation of a professional development program for teachers of high-school engineering. "We wanted to be engaged in defining what the high-school course would be like, and we wanted the teachers to be authentic in providing that course," Allen said in the NSF report.

However, a few months into the grant, input from NSF staff and a request from a school district partner for course materials caused the trio to completely revise their approach. "NSF suggested we develop the requested materials with the ideal high school course in mind," explains Farmer, who now serves as UTeachEngineering project director. "The goal was a year-long, high-quality, low-cost curriculum that could be implemented in a variety of settings."

Rather than create a professional development program, the trio enlisted engineering natural sciences and education faculty, research fellows, practicing engineers–including a NASA engineer–education specialists, and high school teachers, and produced the high-school course, "Engineer Your World." The algebra-based curriculum covers five units–discovering the design process, data acquisition and analysis, reverse engineering of everyday products, systems engineering, and automation and control.

Enriching these five extended design challenges in mechanical, aerospace and civil engineering are week-long explorations that introduce other disciplines such as chemical and biomedical engineering.

In 2011-12, "Engineer Your World" was piloted in seven schools in Texas. That number jumped to 23 schools in eight states for 2012-2013. The plan is to introduce the course in 100 schools in 2013-2014 and double that number in 2014-2015.

Using "Engineer Your World" as a centerpiece, the team returned to their original plan and created several professional development components to complement the course and strengthen the ranks of high-school engineering teachers. UTeachEngineering now includes:

• The Master of Arts in STEM Education-Engineering (MASEE) program aimed at teachers who want to become leaders in secondary engineering education;

• An undergraduate certificate program for students in engineering and the natural sciences (students simultaneously obtain their bachelor of science degrees and teaching certificates);

• A certification program for those who hold bachelor's degrees in engineering or science and would like to teach; and

• A two-week summer session and ongoing support for teachers who teach the "Engineer Your World" course.

Over the next year, UTeachEngineering will add an online learning management system to foster collaboration among current and past participants as well as external resources such as industry mentors.

For more information on the UTeachEngineering program, visit www.uteachengineering.org.