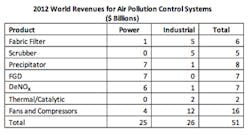

Sales of air pollution control systems will exceed $51 billion this year, with the power industry accounting for nearly half the purchases, according to report by the McIlvaine Company.

McIlvaine says the power plant purchases of DeNOx systems using catalyst will greatly exceed the combined DeNOx and thermal/catalytic systems purchased by industry. There will also be substantial purchases of fans and compressors associated with these systems, according to McIlvaine, as the addition of air pollution control equipment adds backpressure to existing combustion systems, ultimately requiring more frequent replacement of existing system fans.

McIlvaine predicts Asia will account for more than half the air pollution control system purchases, with China alone purchasing more power plant air pollution control equipment than all of the European countries combined.

Some of the largest suppliers are home based in Europe and Japan. China has the leading precipitator companies in terms of revenue generation. The U.S. leads in terms of production of filter media. The U.S. is also the leader in FGD systems. However, McIlvaine says this leadership is based on the inclusion of Alstom, a French company, as a U.S. based supplier. Its air pollution operations are in Tennessee and have been since it acquired Combustion Engineering many years ago.