I live by the philosophy that a perfect pump technology is out there for every application. However, no “one-pump-fits-all” fix exist for any industry, despite how many headaches that would save everyone. Many variables affect the pump selection process. Some are more critical than others, but all are important in providing the end user the best possible solution for his or her application. The strict requirements in the food and beverage industry can present challenges for any one type of pump technology. However, air-operated double diaphragm (AODD) pumps are a solid option for food and beverage applications for a variety of reasons.

Regardless of whether a pump is a diaphragm pump or a centrifugal pump, for food and beverage applications it must be U.S. Food and Drug Administration– (FDA) compliant. The materials that make up the pump are key factors in ensuring that the pump is FDA-compliant. All of the pump components must comply with the FDA’s guidelines for materials that will come in contact with food and beverages. Stainless steel and/or polypropylene are the material options for FDA-compliant AODD pumps. The sturdiness of these materials prevents contamination that other, more porous materials could allow.

Capabilities aplenty

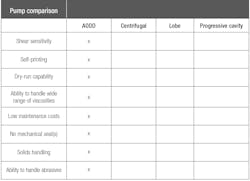

Compared with other pump technologies, diaphragm pumps rate extremely high in diverse capabilities. They can be used to transfer, batch, filter and dispense during different food and beverage applications. Diaphragm pumps can also handle shear-sensitive products, pass solids, run dry, provide variable flow rates, and they do not require electrification or mechanical seals. AODD pumps are portable and can be moved to different locations within one facility, and they are easy to clean for low-maintenance operation. They are also reasonably inexpensive in terms of initial purchase price as well as maintenance and ownership costs. Refer to Table 1 to estimate how other pump technologies might compare to an AODD pump.

AODD pumps in action

Fluids can either be Newtonian or non-Newtonian. Simply put, Newtonian liquids do not change in viscosity regardless of the amount of shear applied to it, while non-Newtonian liquids will. One example of the importance of shear sensitivity is within the craft beer production process. It is fairly common for centrifugal pumps to transfer beer from point A to point B during bottling or canning processes. Northwest Canning, a mobile canning company that services the craft beer industry, experienced issues with how its centrifugal pump affected its products. The issue occurred when the canning process needed to be stopped. Instead of stopping completely, the impeller on the centrifugal pump would continue to spin, creating heat. That heat combined with the shearing of the liquid caused foaming that introduced more oxygen to the beer. The combination of the heat and foam created enough stress on the beer to alter its flavor.

When Northwest Canning switched its centrifugal pump to a diaphragm pump, it no longer had this issue. This is mainly caused by two factors. First, a diaphragm pump has the capability to “deadhead” without damaging the pump or over-pressurizing the system. Deadhead occurs when the discharge line of a pump does not allow the product being pumped to flow (e.g., because of a blockage in the line, or a valve is closed downstream). With most positive displacement pumps, this creates additional pressure that can result in seal failure or worse. With AODD technology, when the discharge pressure of the pump is equivalent to the air inlet pressure being supplied to the pump, it simply stops. Once the pressure is relieved on the discharge side, the pump continues to run. In the scenario mentioned above, this feature solved the heat issue created by the constant rotation of the impeller when the product had nowhere to go. Secondly, without an impeller to cause agitation to the fluid, the foaming issue was eliminated.

The frozen food industry is another sector in which diaphragm pumps are used. A large Mexican food manufacturer in Dallas, Texas, converted almost all of its pumps to AODD pumps. Along with deadhead and shear sensitivity, this manufacturer enjoys the versatility and easy-to-clean features of AODD pumps. The facility can use one pump to transfer a taco sauce, which is thin and close to the viscosity of water. It can use the same pump to transfer a thicker, chunky salsa without damaging the integrity of the vegetables and other ingredients. The manufacturer also uses its AODD pumps to transfer refried beans for burritos, as well as scrambled eggs mixed with potatoes for breakfast tacos.

Table 1. Estimation of how other pump technologies might compare to an AODD pump

Keeping maintenance low & safety high

A good FDA-compliant diaphragm pump should be fitted with single-hinged sanitary clamps at the connections along the fluid path of the pump. These clamps are held together with a hand-tightened tri-clover or a quick knock down fitting. This type of fitting provides easy access to the internal components of the pump. It also supports quick disassembly and reassembly for easy clean-in-place washing with little downtime.

The traditional sanitary diaphragm utilizes two washers that sandwich the diaphragm and hold it in place. This design allows contact between the product being pumped, the washer material (typically stainless steel) and the diaphragm. With the updated single-piece diaphragm, the material being transferred only comes in contact with the diaphragm material on the pump. The single-piece diaphragm pump also supports ease of cleaning because fewer crevices are present for material to get into.

Another benefit of diaphragm pump technology is the simplicity of its design. To operate a diaphragm pump, one only needs an air supply and air filter/regulator. A baseplate, motor, mechanical seal, couplings, coupling guards or gear reducer is not needed. This keeps the up-front purchase and the true cost of ownership low because fewer components are present that require maintenance that could result in downtime.

A growing whiskey and bourbon distillery in Central Texas found that the AODD design also provides a safety factor. When an aged barrel of whiskey is opened, the product inside can be well above 180 proof, making the whiskey highly flammable. The distillery incorporated diaphragm pumps because of their ability to be grounded to prevent contact with voltage. They do not wish to have any potential sparking that can occur from electrified pumps.

It is important to determine what type of pump is the best fit for each application. That being said, with all of the features and benefits of an AODD pump, it should make the list as one of the top choices when beginning the quest for the perfect pump in food and beverage applications.

Bill Marquart is a district sales manager at ARO, a worldwide manufacturer of fluid management products that are expertly engineered to deliver performance and serviceability. For more information about air-operated diaphragm pumps, visit arozone.com.