Proportional valves — which change outputs in proportion to their input value — provide dependable, cost-effective, compact solutions for fast response and consistent control at relatively low flow rates. Proportional control technology is ideal where precise performance is required in variable pressure and flow applications.

Proportional valves may be perceived as more complicated than other solenoid valves, but understanding and applying them appropriately can yield real benefits once a few simple concepts and differentiators are grasped.

Not all proportional valves are created equal. When original equipment manufacturers (OEMs), integrators and end users are selecting proportional valves, they should consider a few key questions as early as possible in the application development process:

- Is the intended application suitable for a proportional valve?

- Does the application require an air-piloted or a direct-acting model?

- Would a proportional valve with special capabilities — such as software-based tuning — help?

The goal of answering these questions is to ensure the selection of the correct valve for the needs of the application for which it is being employed.

Proportional valve applications

In valve selection, the application is everything. To ensure the best result, specifiers and users must closely consider relevant characteristics of the application that will determine future valve performance.

It is important to consider if the application is static or dynamic. In a static application, the set point of desired pressure, flow, etc., to be controlled by valve opening and closing remains fixed for the great majority of the time. For example, in leak testing, the valve applies a fixed pressure to a component, testing for soundness. This fixed set point pressure need change only when a different type of component is to be tested.

By contrast, a dynamic application is one wherein the set point must frequently change, so the valve opens and closes frequently or continuously. For example, in material testing, the pressure output of the valve is steadily increased until the tested material reaches its point of failure.

Dynamic applications usually demand a more robust type of proportional valve, and also share these other characteristics:

- Frequently commanded pressure changes, with heavy-duty cycling (valve opening and closing)

- Shifting loads with backpressure, requiring continual firing/adjustment

- Frequently changing flow rates

- Additional factors that may be considered before selecting a proportional valve include:

- Air, oxygen, nitrogen, steam, etc., and temperature

- Flow: Cv, SCFM (consider required filtration)

- Pressure: inlet pressure, output pressure range, pressure drop

- Atmosphere: temperature, explosion-proof, watertight

- Power: 24 VDC, 12 VDC, etc., and maximum wattage

- Loss of power operation: pressure held, pressure released

- Other: vacuum control, special construction

Specifiers and users should consult their valve manufacturer regarding any additional valve selection factors.

Typical proportional valve applications

- Web/roll tensioning (converting, textiles, paper)

- Laser cutting

- Leak testing

- Fluid spraying or coating (paint, glue, other)

- Medical (air bag, vacuum, other)

- Spot welding

- PET blowing

- Tire balancing & tensioning

- Analytical instrumentation

Application benefits

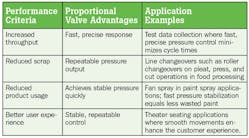

Proportional control has advantages in the following applications:

Proportional Valve Advantages

Direct actuation versus air-piloted actuation

Proportional valve technologies are available using a variety of operating methods. Operators may include the following:

Direct-acting proportional coil solenoids: Act directly on pistons or spools to adjust valve open or closed positions, based on varying voltage across the coil.

Pulsed air-piloted solenoids: Load and unload air pressure in a pilot control chamber to move a diaphragm, which in turn acts on a piston to open or close the valve.

Piezoelectric operators: Deform to either open or close the valve when voltage is applied.

Pneumatic positioners: Act as pilots, enabling air to enter or vent from a diaphragm or cylinder to open or close a much larger valve.

Piezoelectric operators are applied mostly where extremely low power consumption is necessary, while positioners are utilized almost exclusively at quite large capacities and flow rates. Most users’ applications fall in the middle ground. Here the comparison of air-piloted versus direct-acting valves deserves careful consideration of pros and cons, depending on specific application and machine design requirements.

Air-piloted: Air-piloted proportional valves are often chosen by users and specifiers whose applications require lower power consumption, or whose budgets demand a lower purchase price. In fact, the air-piloted type is probably the most frequently purchased class of proportional valve.

Courtesy ASCO Numatics

However, these models use wearable components such as rolling diaphragms and pulsed solenoid pilot valves to move the piston to regulate pressure. This renders air-piloted valves less suited to applications with constantly changing set points, which produce heavy solenoid cycling rates that can soon wear out these components. Worn components can result in degraded performance and excess air consumption. So these valves may perform well in static control tasks, but may be less appropriate in dynamic applications.

Finally, air-piloted models typically offer minimal adjustment capabilities to optimize performance.

READ ALSO: Control Valve Actuator Bench Set Requirements

Direct-acting proportional coil solenoid valves are less suited than air-piloted models to applications requiring the smallest power consumption or the lowest purchase price.

However, they may actually offer greater advantages than their more popular counterparts. They fit a considerably wider range of applications, and their simpler construction (with fewer mechanical parts) and principles of operation generally result in more dependable performance.

In fact, the more robust construction of direct-acting proportional coil solenoid valves often substantially increases their service life compared to air-piloted proportional valves. This renders the direct-acting types more appropriate in dynamic applications where wearable components prove less durable.

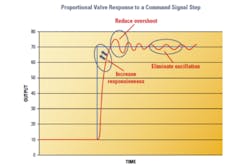

In addition to improved robustness, the direct-acting design provides several other technical advantages. Overshoot is a tendency to accelerate toward the set point and then go past it, having to reverse back toward it — perhaps going past it again in the other direction, and so on. Common in many systems that are tuned for short response times, these oscillations typically take less time to settle in direct-acting proportional coil designs. The overshoot settling time is short because the valve directly moves the piston by varying current to the coil.

By contrast, air-piloted solenoid valves must move air into and out of a pilot control chamber. This is a slower process reliant upon pilot valve cycle rates.

Direct-acting proportional coil designs also typically provide a finer resolution of pressure control, which can be critical in some applications. For example, some polishing applications demand small pressure changes to avoid damaging parts. Direct-acting units achieve this by precisely varying coil current to make very controlled pressure adjustments. Solenoid air-piloted units have stepped pressure adjustments based on pilot valve cycle times that can result in pressure swings that are too large in some applications. The direct-acting design possesses greater speed, responsiveness, and resolution that makes it superior to air-piloted designs for a number of applications.

Tuning software

Air-piloted proportional pressure regulators commonly offer a handful of settings to accommodate varying application requirements. However, these canned settings can meet with limited success for a number of applications. And even proportional pressure control valves that can be adjusted for specific applications typically do so only in one of two ways:

- They may require a time-consuming series of physical adjustments at the factory. These often demand lengthy back-and-forth consultations with customers to match the valve with the application.

- A valve design may allow direct adjustments (via screwdriver to manual potentiometers) in the field. Unfortunately, this method lacks precision — and offers little hope of adjusting each valve in an assembly identically.

Instead, for many applications, users should consider direct-acting solenoid valves featuring newer valve technology that offers digital tuning software. For example, parameter adjustment software incorporating a digital oscilloscope supplies quick, easy adjustments that provide vital benefits for many applications.

Such software places a welcome amount of control in users’ hands. It gives them the power to change almost any setting — including dead band, analog signal type, and shutoff level. In the prototype stage of OEM assembly, design engineers can immediately see the effects of any changes they make; for instance, they can quickly and easily fine-tune the pressure received by a cylinder to obtain a specific force. If necessary, they can make these real-time changes while on the phone receiving expert advice from the manufacturer’s tech support specialists. These features all increase speed to market by allowing an OEM to modify the proportional valve as needed during design revisions.

Tuning software advantages

- Offers high-precision pressure control

- Streamlines development

- Allows adjusting the valve for the application in-situ

- Enables parameters to be saved and emailed to tech support

- Allows restoral of factory settings

- For OEMs, permits pre-setting of valve parameters at factory

- Supplies best product performance for suitable applications

This type of software enables much faster tuning and resolution of issues or questions. Users can often make and validate a change in seconds, instead of days or weeks. (NOTE: While dynamic applications are often the best candidates for tuning software, applications with ultra-stable pressure control, such as in leak testing situations, may also greatly benefit.)

In conclusion

Proportional solenoid valves offer important advantages in the right applications.

Typical proportional valve advantages

- Proportional control valves offer precise performance in a number of applications with more variable pressure, flow, etc.

- Understanding some simple concepts can make specifying or purchasing proportional valves easier

- Though both have their place, direct-acting proportional control valves can deliver surprising advantages over solenoid air-piloted models

- Some direct-acting proportional valves offer new digital tuning software that enables specifiers and users to precisely fit their valves to their applications

Prospective purchasers should evaluate their choices carefully, considering application demands, type of control required, valve service life, and useful new technologies such as software-based digital tuning. Weighing these factors in making a final proportional valve selection can help save time, effort, and cost for OEMs, integrators, and end-users.

Tom Voth

Tom Voth is a product marketing manager for Proportional Products at ASCO Numatics, an Emerson company. Voth earned his bachelor’s degree in Mechanical Engineering and has five years’ experience specifying and customizing proportional valves to optimize performance. Mr. Voth can be reached at [email protected].