This is the sixth and final part of a series of articles based on Optimizing Pumping Systems: A Guide to Improved Energy Efficiency, Reliability, and Profitability, authored by pump systems experts. This new guidebook continues the mission of Pump Systems Matter and the Hydraulic Institute to advance knowledge of pumping systems.

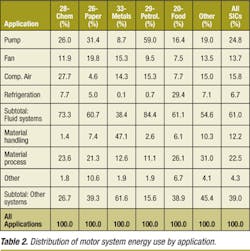

In U.S.-based industrial plants, more than 40 million electric motors convert electricity into useful work. Nearly 60 percent of all electricity used by industry is consumed by these motor systems. Increasing the energy efficiency of these existing motor systems can lead to dramatic energy savings nationwide. Pump system optimization is one of the most significant ways to affect improvement.

Many installed pumping systems operate below best efficiency. Slight improvements in component efficiency will yield nominal reductions in energy costs; however, pumping system optimization can reduce energy costs substantially, often by more than 20 percent.

Installed pumping systems operating below best efficiency frequently experience above average failure rates. Between 1991 and 1994, the Finnish Maintenance Society studied 20 plants and the performance of 1690 pumps. The pump malfunctions were observed and categorized into individual fault types under eight representative groupings (Table 1).

Economic justification of a pumping system improvement is pivotal to management’s decision to advance or abandon the project. Development of a successful system optimization LCC (life cycle cost) program with a focus on the bottom line can determine the viability of a project.

Potential Energy Savings

Even properly maintained motors have a finite life. Motor winding insulation eventually breaks down, even in those motors that have received meticulous preventative maintenance throughout their lives. For motors below 37 kW (50 hp), the most common remedy is simply to replace the failed motor with an equivalent one. In higher power applications, it may seem more economical to rewind an existing motor; however, it is important to note that the rewinding process may, in fact, reduce the rated motor efficiency. High-efficiency motors should be considered in such cases, since they are typically 3 percent to 8 percent more efficient than standard motors. In high-use applications, this efficiency advantage often provides an attractive payback period.

Component Approach

Plants are usually assembled as components or part of a process/component. The components are typically supplied by manufacturers that specialize in that field. When an engineering, procurement, and construction (EPC) organization issues the bid packages for a plant, the package typically contains only the specifications related to the individual bidder’s products. This practice prevents the respective component suppliers from fully understanding how their products will be applied and may result in misapplied, inefficient equipment installations, specifically pumps and motors.

Similar to the way that a predictive maintenance (PM) schedule is developed to minimize expensive repairs, a well-designed system can avoid higher-than-necessary operating costs. Using a life cycle cost perspective during initial system design, or while planning system upgrades and modifications, can reduce operating costs and improve system reliability.

Overly Conservative or Improper Pump SelectionUnfortunately, oversizing pumps adds to system operating costs in terms of both energy and maintenance requirements. These costs are often overlooked and not fully understood during the system specification process. Because many of these operating and maintenance costs are avoidable, correcting an oversized pump can be a cost-effective system improvement.

Installation & Operation

Initial installation of a pumping system, particularly the sub-base preparation, is critical to the life cycle cost. Structurally or mechanically loose rotating machinery will experience higher levels of vibration leading directly to increased wear.

Pumps are often used to maintain fluid levels in tanks by draining or filling them as required. Many systems rely on a level control to activate the pumps automatically. Small tanks with oversized pumps will start and stop frequently as they work to maintain the desired liquid level. This practice can lead to unreliable pump operation, especially in large pumps. Large pump motors have high starting currents, and repeated stopping and restarting a pump can accelerate wear of the motor controllers and dynamic surfaces in the pump/motor assembly, leading to unreliable pump system operation. The mechanical seals in many pumps rely on a lubricating film of system fluid that develops within the first two revolutions and over time, repeated start-ups accelerate seal wear. Pump/motor applications designed to handle repeated starting and stopping should be carefully analyzed.

Maintenance

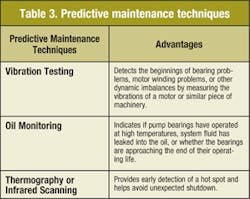

Problems such as cavitation, frequent energizing and de-energizing of a pump motor, and valve seat leakage can increase maintenance requirements and decrease the length of time between repairs. Seal and bearing manufacturers often provide a mean time between failures (MTBF) for a particular product. If the actual time to failure is significantly less than the manufacturer’s recommended interval, the cause of the failure should be assessed. Predictive maintenance techniques determine the rate at which a problem is developing and allow operators to plan for equipment repairs. Some predictive maintenance techniques and their advantages are listed in Table 3.

These techniques, combined with examination of the signatures and history of previously recorded data, can help the operators assess the rate at which a problem is developing and determine whether immediate repairs are necessary or if equipment repairs can be scheduled at an optimum time.

Making a Business Case

Plant and corporate managers are often bound by a concern for a company’s profits when considering the investment of capital funds. Decision makers are usually attuned to activities that translate directly to the bottom line. Fortunately, many energy-efficiency projects provide additional benefits that may not be immediately apparent to plant and corporate managers. These benefits include:

• Increased productivity

• Lower maintenance costs

• Reduced costs of environmental compliance

• Lower production costs

• Reduced waste disposal costs

• Improved product quality

• Improved capacity utilization

• Improved reliability

• Improved worker safety

Reduced energy costs coupled with these benefits should be a strong incentive for implementing a pumping system project. However, some corporate managers may need to be reminded of the benefits of energy cost savings. The investment that improves pump system efficiency will yield annual savings via reduced energy costs and may therefore be viewed as a new source for capital income to the corporation. Additionally, increased pumping system efficiency may capture shareholder value.

The financial analysis of a pumping system investment should include the time value of money and be represented in one of the following ways:

• Net present value

• Internal rate of return

• Life cycle costs

• True cost of energy

Life Cycle Costing

How to Increase the Energy Efficiency of Your Pumping System

Optimizing Pumping Systems is a publication designed for those who need to understand details to accomplish projects and make key capital and budget decisions. It is easy to read and filled with drawings and reference tables. It provides information on optimizing existing pumping systems and designing new pumping systems that run at optimum efficiency for a reduction in energy use.

To purchase your copy, visit the HI e-Store at www.Pumps.org or estore.Pumps.org.

Pump Systems Matter also offers a day-long course on pumping system optimization, based on the guidebook, for individuals who wish to learn the fundamentals of doing a basic pump system assessment. Host organizations can sponsor the course for in-house training and utilities. Energy efficiency NGOs, and state energy offices are eligible to sponsor the course for their client organizations – particularly the pump user community. For more information, please visit www.PumpSystemsMatter.org or www.Pumps.org.

Guidebooks for Pumping Systems Success

Identifying which component in your system is causing a drop in pump performance or determining what caused vibration levels to increase can be time-consuming endeavors. The Hydraulic Institute published the following four guidebooks to help ease the process of identifying the culprits of such troublesome application scenarios:

1. Variable Speed Pumping: A Guide to Successful Applications

2. Pump Life Cycle Costs: A Guide to LCC Analysis for Pumping Systems

3. Optimizing Pumping Systems: A Guide for Improved Energy Efficiency, Reliability, & Profitability

4. Mechanical Seals for Pumps: Application Guidelines

The guidebooks are designed to help users:

• Understand how components work as a system.

• Reduce the amount of energy your system uses.

• Increase Mean Time Between Repairs (MTBR).

• Keep liquids flowing at the required rate.

• Troubleshoot new symptoms of failure.

• Select the correct replacement part.

• Protect the quality of the product.

• Avoid unanticipated shutdowns.

A four-book package may be purchased at

estore.pumps.org/Energy-Package-LCC-VSP-OPS-Seals-Guides-P51C13.aspx.

A three-book package, including items two, three, and four from the list above, may be purchased at estore.pumps.org/Energy-Package-LCC-VSP-OPS-Seals-Guides-P51C13.aspx.

A payback period is the time required for the net benefits of an investment to accrue to the point where they equal the cost of the initial outlay. For a project that returns benefits in consistent annual increments, the simple payback is equal to the initial investment divided by the annual benefit. The simplicity of simple payback makes it an ideal measure of project economics for use by plant and corporate managers in quick decisions. It is important to note that simple payback is an approximation and does not take into account the time value of money. More sophisticated analyses that take into account factors such as discount rates, tax impacts, and the cost of capital include net present value and internal rate of return.

Analyzing from an Integrated System Perspective: Many organizations consider only the initial purchase and installation costs of a system. However, plant designers and managers will benefit from evaluating the LCC of different solutions before installing major new equipment or carrying out a major overhaul to identify the most financially attractive alternative. Plant operations can be a significant source of savings, especially because energy-efficient equipment can minimize energy consumption and plant downtime.

For new pumping system procurements, note that new piping system design technology uses numerical optimization techniques, which provide a practical way to treat the pipe system as a variable at the design stage. A well-designed system will last longer than other types, and this should be taken into account in an LCC analysis.

Making Pump System Improvement Attractive

A proposal for a pumping system improvement project can be made attractive to corporate decision makers if the facility manager does the following:

• Identifies opportunities for improving pumping system efficiency

• Determines the life cycle cost of attaining each option

• Identifies the option(s) with the greatest net benefits

• Collaborates with financial staff to identify current corporate priorities

• Generates a proposal that demonstrates how the benefits of the pumping system project will directly respond to current corporate needs

Developing successful energy projects begins with laying the groundwork to support the project. Ideally, it starts with a facility reward program for cost-saving capital equipment projects and appropriately recognizes employees for their efforts. However, most of the time, the groundwork is done by a motivated individual who takes pride in the job and is inspired by what other facilities have done.

Gregg Romanyshyn is the technical director at the Hydraulic Institute. In this position, he oversees the technical aspects related to the Hydraulic Institute. Mr. Romanyshyn has over 30 years experience involved with pump related businesses and has been at the Hydraulic Institute for 10 years. The Hydraulic Institute is the largest association of pump industry manufacturers in North America and serves the pump community by providing product standards, guidelines, and references, and is a forum for the exchange of industry information. www.PumpSystemsMatter.orgReferences

1. ANSI/HI Pump Standards. For more information on these standards visit estore.Pumps.org.

2. Optimizing Pumping Systems, A Guide to Improved Energy Efficiency, Reliability, and Profitability. For more information on HI Guidebooks, visit www.Pumps.org.

Hydraulic Institute Members and Pump Systems Matter Sponsors contributed to the content of this article.