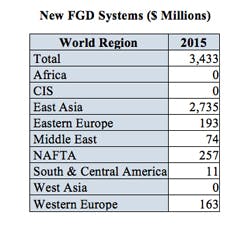

The total global market for FGD systems and components will exceed $8 billion in 2015, with new systems accounting for $3.4 billion, according to the latest forecast from the McIlvaine Company. Sales of new FGD systems next year will be primarily in East Asia and the major replacement and retrofit markets will be in Europe and the U.S. However, China will be a leader in replacement as well as new systems, according to the FGD Market and Strategies report.

READ ALSO: Brazilian Engineering Student Turns Emissions Into Energy to Win Honeywell Design Challenge

The report says there could possibly be one new coal-fired power plant in the U.S. ordered in 2015 and the retrofit of FGD systems to existing power plants will be modest due to the decision by some operators to use dry-sorbent injection rather than scrubbers. The Chinese market will include scrubbers for many new power plants as well and continues to be a large market for replacement of older FGD systems, which have not met efficiency requirements.

Eastern Europe will continue to complete its FGD program, McIlvaine reports, while Western Europe is now realizing that coal will be a necessary part of the fuel mix for the foreseeable future. As a result, there will continue to be replacements of older systems, which are now more than 30 years old.

The use of wet scrubbing with limestone as the reagent and gypsum as the byproduct will continue to dominate the world scene, according to McIlvaine. However, there will increasingly be selections of alternative technologies including wet lime, dry lime, ammonium sulfate, double alkali, direct sorbent injection and hot catalytic filtration with sorbent for SO2 removal.