Non-Revenue Water … It’s what keeps water system managers up at night.

In lay terms, Non-Revenue Water (NRW) is the difference between the amount of water produced at the treatment plant and the amount of water actually billed to the customer. In the United States, most water distribution systems are an aging maze of pipes and valves and pumping stations, fraught with any number of opportunities for water to make the mysterious transition from revenue to non-revenue status.

NRW is also referred to as "lost water." Water can get lost in reality through leaks in the water distribution system (physical losses), or it can get lost apparently through theft or metering inaccuracies. For a large distribution system, it is not uncommon for millions of gallons of water per day to get "lost." In fact, the industry average for NRW is an alarmingly high 18 percent.

The Non-Revenue Water Challenge

The core challenge most water distribution system managers face in troubleshooting NRW is identifying the sources of water loss. With hundreds or thousands of miles of main in an average-sized system, finding the root causes of NRW is a guessing game with tremendously steep odds. Further, the cost of guessing wrong — i.e., work hours spent digging unnecessary holes in the ground — is significant, while the cost of not finding the source of NRW may be even more severe, as small pipe leaks may lead to larger and more damaging water main breaks.

For those who live in or near older cities in the United States, water main breaks are an increasingly common occurrence. In July 2014, a 93-year-old underground water main broke in Los Angeles, spilling an estimated 8–10 million gallons of water, flooding parts of the campus of UCLA, and forcing the closure of Sunset Boulevard. Extreme events of this sort figure to become more commonplace if something isn’t done to enable early identification of leaks in water distribution systems.

READ ALSO: Stormwater Solutions — How green infrastructure is being leveraged to solve real-world challenges

While leaks are typically the most prominent source of NRW, particularly where old infrastructure is in place, other sources include theft and metering errors. Billing meters are subject to error, and where those errors are skewed toward lower-than-actual readings, they will result in NRW. From a theft perspective, the illegal tapping of fire hydrants is also a concern.

Further complicating the NRW challenge in the U.S. is the lack of funding to implement new technology solutions and/or replace aging water infrastructure. In the current economic climate, billing and tax increases are highly scrutinized, which leaves little in the way of flexibility to make the necessary system improvements to minimize NRW. As such, water distribution companies must be creative in identifying solutions to water loss that provide a definitive payback.

District Metered Areas

District Metered Areas (DMAs) can be used to effectively detect leaks and troubleshoot water loss in a distribution system. In fact, this practice has been commonly used in the United Kingdom since the 1980s. While it has yet to achieve widespread use in the United States, there are some projects that show movement in the direction of the DMA approach as infrastructure continues to age and water loss becomes a more troublesome issue for municipalities.

The DMA technique divides the distribution system into smaller, more manageable segments by establishing permanent boundaries. Flowmeters are then introduced at strategic locations in each segment (DMA) that allow the manager of the distribution system to monitor flows in specific areas of the network to more effectively determine water loss locations.

The International Water Association’s District Metered Areas Guidance Notes report describes the DMA dynamic as follows:

"The traditional approach to leakage control has been a passive one, whereby the leak is repaired only when it becomes visible. The development of acoustic instruments has significantly improved the situation, allowing invisible leaks to be located as well. But the application of such instruments over the whole of a large water network is an expensive and time-consuming activity. The solution is a permanent leakage control system whereby the network is divided into District Metered Areas (DMAs) supplied by a limited number of key mains, on which flowmeters are installed. In this way it is possible to regularly quantify the leakage level in each DMA so that the leakage location activity is always directed to the worst parts of the network."

Pressure control is a key factor in the quest to minimize leaks in a water distribution system. DMAs present an additional opportunity to reduce pressure in each segment of the system, thus reducing the flow rate and frequency of annual pipe bursts. While most distribution networks, particularly in the United States, are managed without DMAs, the International Water Association says those that have successfully achieved low leakage rates without DMAs have high-quality infrastructure in good condition, an efficient repair operation, and low, stable pressures. In the United States, most water utilities are struggling with aging and antiquated infrastructure. In fact, a 2012 American Water Works Association study found that more than $1 trillion will be needed to replace and expand drinking water infrastructure over the next 25 years, and wastewater costs are thought to be similar.

Continued on next page

Applying the District Metered Area Approach

United Water is a subsidiary of Suez Environnement that specializes in partnering with municipalities and industries to maximize the performance of existing water and wastewater infrastructure. In this capacity, United Water is currently engaged in a large-scale DMA project involving its service areas in the city of New Rochelle, New York, and a portion of neighboring Westchester County, which aims to reduce NRW in the region to the industry standard of 18 percent or less. At the start of the project, NRW in the service areas was in the 25-30 percent range, and at the time of this writing it was in the range of 20 percent.

All told, the United Water project covers a distribution system that delivers more than 6.5 billion gallons of water annually through 426 miles of main in New Rochelle and 2 billion gallons of water annually through 168 miles of main in Westchester. Since its New Rochelle system purchases all of its water from the New York City Department of Environmental Protection and Westchester purchases its water through Westchester Water Works and Aquarion Water Company, NRW is a high-cost issue for United Water and the municipalities it is servicing in this case.

United Water identified its New Rochelle and Westchester systems as targets for the DMA approach because both were dealing with a high degree of water loss. Westchester was also seen as an optimal test case for the DMA program because it was small compared to other business units and could more easily be leveraged as a proof-of-concept for the associated technology and systems.

Ultimately, United Water’s goal for the New Rochelle and Westchester DMA program was to get the production side to align as closely as possible with the consumption side across smaller regions of the system. One of the key challenges associated with segmenting the distribution network into metered areas was minimizing the number of closed valves required for zone isolation and the number of flowmeters required to generate the necessary measurements into and out of any area. Any flow path crossing the boundaries of a segment had to have a meter and/or closed valves.

With this in mind, United Water designed the DMA network with as many natural boundaries as possible, determining where closed valves made sense and where the impact was too much and called for a metering system. When the design was complete, the New Rochelle and Westchester networks were subdivided into 19 submetering districts comprised of 62 DMA flowmeters with pressure sensors and an additional 23 pressure monitoring locations. The result was a system that provided more intelligence and insight to enable more effective and efficient troubleshooting capability to address water loss in any zone.

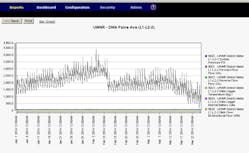

The key to the DMA approach is accurate measurement and calculation of the flow into a given zone minus the flow out of a given zone. This is called the mass flow balance, and it enables each DMA to be treated as its own system independent of the other DMAs and overall system. "This allows United Water to target its resources on the most problematic zone," says Nick Curcio, Non-Revenue Water Manager for United Water New York. "It reduces the search area for issues, allowing for a quicker find, quicker fix, and less loss of water."

The DMA approach has been working well for United Water in New Rochelle and Westchester, and the network now has five people dedicated to leak detection because the number of leaks being identified and isolated has risen so quickly. In fact, on one occasion United Water found low flow in the system and was able to identify the issue as a product of reduced flow into the system from one of its suppliers. In the past, it may have taken months or more to find the source of a low-flow scenario of this sort, but the segmentation of the network enabled the source to be isolated to a supplier-fed area.

"We’re using individual flow and combining pressure data to more effectively isolate troubleshooting," says Keith Kolkebeck, director of technology solutions for United Water. "We now have continuous monitoring of the system, and we’re isolating leaks and saving money."

The Technology Solution

Technology was a crucial piece of the United Water DMA approach, with a flowmeter at the heart of the system. United Water used four main criteria when selecting the flowmeter for its pilot study:

- The flowmeter had to be battery-powered with a minimum five-year battery life. Wiring to each meter in the DMA system would have presented an oppressive cost, rendering the project unviable.

- The flowmeter had to integrate with United Water’s enhanced metering system (Advanced Metering Infrastructure) and a DMA data logger at the same time.

- The flowmeter needed to provide an accuracy across the system’s flow range of +/-1 percent under average flow conditions.

- The cost of the flowmeter technology was an important factor.

- The meter needed the capability to be direct-buried to avoid the cost and operational issues associated with installing and maintaining meter pits.

Upon completion of its technology evaluation, United Water specified the Siemens SITRANS FM MAG 8000 battery-powered flowmeter. "The FM MAG was ideal for the application because it offered 10-year maintenance-free battery life and AMR/AMI capability," says Brian Roughan, a senior account manager for Siemens. "Normally United Water will size each application one to two pipe sizes below the actual pipe. In addition to that, United Water decided to go with 0.2 percent accuracy, rather than the standard 0.4 percent accuracy, which allowed them to have higher performance for precise flow measurement." Roughan says the no-moving-parts design of the FM MAG was another key advantage, as it minimized the maintenance requirement.

According to Curcio, before sizing the flowmeter technology, United Water went to great lengths to ensure its flow model was spot-on and validated. The decision on the meter size was based on the hydraulic model evaluations. The goal was to size a meter for every possible location with a 1 percent accuracy on a weighted average basis. Low flow conditions over the winter were targeted for 2 percent or better accuracy. Summers, when there was high flow, produced 1 percent or better accuracy. Based on the flow model, a 12" magnetic flowmeter was specified for a 24" line because that was the size that provided the average 1 percent accuracy the application required.

“What’s important here was that we chose the optimal meter size for the flow at each meter location, not the pipe size," says Curcio, who says downsizing the flowmeters actually sacrificed very little in terms of pressure drop. In sizing the flowmeter for the application, Curcio says United Water considered meter size, straight length, and multiplied for max flow, and the results never eclipsed one foot of head loss, with just a fraction of a PSI being sacrificed. "Once you saw the numbers, the decision was made for us," says Curcio.

United Water’s pilot study analyzed the viability of the DMA approach. Initially, there was some pushback related to the cost and safety of the system, as the preliminary design called for the meters to be installed in a manhole with personnel manually collecting data from the flowmeters. United Water worked to devise a solution that modified a standard concrete utility box to house electronics on the side of the road. For a direct burial application the meter body is located underground and the transmitter and battery are remotely mounted above the ground in the utility box next to the datalogger. This allows for easy access, thus eliminating the need to access a manhole to retrieve data.

"Once we understood the capabilities of the flowmeter and with the development of a new electronics box, [we] decided to direct bury the flowmeters," says Curcio. "These two techniques greatly reduced the installation costs and the ongoing operating cost. The biggest benefit is that our employees are able to safely work on the equipment."

Once the safety and benefits of the DMA approach were fully communicated to stakeholders, Curcio says implementation of a DMA system was clearly determined to be in line with United Water’s long-term strategic plan while providing the best return on investment. "The team worked collaboratively with the regulator regarding the project," says Curcio. "We demonstrated that a DMA system would help United Water operate its distribution system more efficiently, reducing the long-term costs to our customers by reducing the cost to operate our system."

The team also worked with municipalities regarding appropriate permitting and design. "Our employees were trained on the new technology," says Curcio. "They have enthusiastically embraced the system as they can identify leaks quickly and respond to customer concerns."

Final Results

With its DMA approach, United Water now has the ability to continuously monitor its distribution network. "We continue to refine and fine-tune the model so we can detect leaks earlier in the cycle," says Kokebeck. "The mass flow balance is already allowing us to detect leaks early in the game – even those that aren’t surfacing – and save millions of gallons of flow."

Beyond the NRW impact, United Water is now digging fewer dry holes, which cuts down on man hours, safety issues, and the cost of maintaining the network. The next step for United Water is to combine what it has learned so far about the production side of the network with data it is gathering on the consumption side of the business.

"It will be interesting to see how this high-resolution data will impact the cost savings over time." says Curcio.

www.siemens.com/industry

www.unitedwater.com

References

1. "District Metered Areas, Guidance Notes," Feb. 2007, Version 1, International Water Association, Water Loss Task Force.

2. "Leakage Management Technologies," 2007, AWWA Research Foundation, U.S. Environmental Protection Agency.

Matt Migliore is the director of content for Flow Control magazine and FlowControlNetwork.com. He has covered technology and industry for 12-plus years. Matt can be reached at 610 828-1711 or [email protected].