A new gaseous fuel combustion technology is designed to reduce environmental emissions of nitrogen oxides (NOx), a highly regulated pollutant in industrial applications, to the low levels required by the most stringent regulations in the country, while enhancing heat transfer characteristics. The technology has been successfully implemented in Once-Through Steam Generators (OTSGs) in Enhanced Oil Recovery (EOR) applications, and more recently in refinery process heaters.

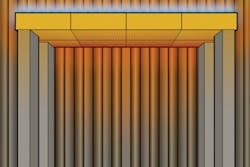

The technology incorporates a high-temperature porous ceramic matrix (i.e., the solution’s surface) positioned at a distance a few feet away from where the fuel and air are introduced in the furnace (see Figure 1). Fuel and air are thoroughly mixed before reaching the surface. The fuel/air jet entrains internal flue gases, diluting the mixture. The diluted mixture is then ignited by the hot, glowing surface where the bulk of the combustion process takes place within the matrix porous passages. The technology provides an effective combustion stabilization, flame confinement and radiation source.

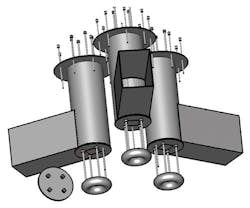

Figure 2. Modes Transition Duplex mode of operation

The technology integrates several NOx reduction techniques that combine to deliver extremely low NOx emission levels:

- Premixed combustion behavior — Fuel and air are introduced in the furnace in a manner consistent with a diffusion flame burner; However, in contrast with conventional raw gas burners in which ignition takes place at the burner throat immediately after the fuel and air start mixing, ignition does not take place until fuel and air reach the surface. Although fuel/ air injection is configured as a diffusion system, fuel and air have the opportunity to thoroughly mix as they travel the distance before ignition occurs. The system behaves as a premixed system with its inherent NOx reduction benefits but without the disadvantages of premixed combustion (i.e., flashback).

- Fuel/air mixture dilution — Internal flue gas is entrained along the length that the fuel/air jet travels, providing enhanced dilution of the jet. This dilution contributes to reduced peak flame temperatures for better control of thermal NOx.

- Radiation cooling — Because combustion primarily occurs within the surface, the majority of the energy transfer takes place as solid body radiation (gray body). Solid body radiation is a considerably more effective energy transfer mechanism than flame radiation, the primary energy transfer in conventional burners. This is because of the highly spectrally dependent manner in which gaseous fuel flames radiate energy. The enhanced radiation heat transfer contributes to thermal NOx reduction by radiative cooling of the flame.

In addition to being able to operate with NOx low emissions, the technology has shown to provide other benefits:

- Elimination of flame impingement — An NOx reduction strategy in the design of ultra-low NOx (ULN) burners incorporates delayed fuel/ air mixing (i.e., flame stretching). Unfortunately, stretching flames creates buoyant flames that are often impacted by furnace currents or that coalesce with adjacent flames, leading to flame impingement on process tubes or shock tubes in the convection section. Here, combustion is confined within the surface to eliminate any possibility for flame impingement.

- Enhanced CO oxidation — Fuel and air are thoroughly mixed prior to ignition, eliminating fuel-rich and fuel-lean zones that may contribute to CO production in conventional burners. Furthermore, uniform temperatures on the surface enhance CO oxidation.

- Enhanced radiation heat transfer — As previously described, a considerable enhancement in radiation heat transfer over conventional burner flames is provided as it radiates energy as a gray body. Radiation is further improved by the porous nature of the surface. The cavities in the porous surface enhance emissivity properties of the high-temperature ceramic material as a result of the apparent emissivity phenomena.

- Noise reduction — Laboratory experiments demonstrated that sound pressure levels can be reduced from an average of 85 decibels (dB) in burner mode to an average of 72 dB in the new mode. This is attributed to the fact that the turbulent nature of combustion is essentially eliminated as laminar combustion takes place mostly within thousands of small cavities in the surface.

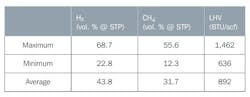

Table 1. Fuel composition

New modes of operation

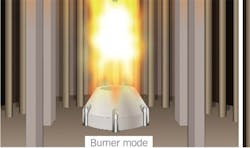

- Cold furnace startup and warmup (burner-mode operation) — Conventional process heater startup procedures are followed. That is, burner pilots are ignited followed by proof of ignition. Burner ignition follows according to standard refinery process heater and burner procedures. The heater operates in burner mode (i.e., flames stabilized at the burner throat/tile) during the furnace and surface warmup period. Standard burner ramp-up and furnace soaking periods should be followed.

- Transition — Once the standard heater warmup procedures have been met, the surface temperature is verified to ensure it is above the ignition temperature of the gas. No direct ignition temperature measurement is taken, but the temperature is typically correlated to the heater bridge wall temperature and/or the Duplex surface glow. Once ignition temperatures are verified, fuel supply to the burner nozzles is interrupted and fuel supply to the fuel nozzles is started concurrently, effecting transition to operation. A few seconds later and upon confirmation of operation, burner pilots are shut off.

- New mode operation — Once transition has been accomplished, the heater can be ramped up to its design capacity

.

Figure 3. Burner modifications

Retrofit in a refinery process heater

The technology was retrofitted in a vertical cylindrical (VC) reformer splitter reboiler process heater at a refinery in California. The project objective was to meet NOx emissions less than or equal to six parts per million (ppm), corrected at 3 percent oxygen (O2) (less than or equal to 0.007 pounds of NOx/million British Thermal Unit [MMBtu]) over a wide range of refinery process conditions.

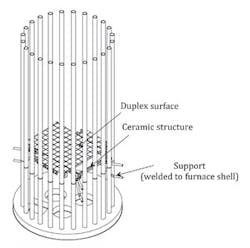

Figure 4. Duplex surface

The reboiler VC furnace heats fluid fed from a distillation tower that fractionates process fluid fed from a reformer unit ("the unit"). The heater’s radiant section dimensions are: outside shell diameter of 9 feet and 6½ inches and height of 17 feet and 8½ inches. Three natural draft ultra-low NOx ULN burners with a maximum capacity of 3.75 MMBtu/hour each are installed on the furnace floor firing refinery fuel gas vertically up. Historical refinery fuel compositions obtained over a 24-week period immediately prior to the initiation of the testing activities were obtained. A summary of selected data is presented in Table 1.

The retrofit into the VC process heater took less than two days of furnace downtime. It involved the following:

- Modifications to the existing burners were made to make the existing UNL burners compatible with operation. The existing fuel manifolds, risers and tips were kept intact and separate fuel manifolds, risers and tips were installed. Figure 3 is a schematic representation of the burner modifications that were made to the existing ULN burners installed in the VC heater. A doughnut-shaped fuel manifold was added at the bottom of each burner. Each Duplex manifold delivers fuel to four risers with Duplex tips positioned in the burner throat within the core of the air supply. Valves in each burner fuel supply lines were installed to provide independent fuel supply to accommodate burner-mode operation and new-mode operation.

- Surface. A surface ceramic structure resting on supports welded to the furnace shell was installed. The high-temperature porous ceramic matrix rested on this structure (see Figure 4).

- Instrumentation. Additional valving and instrumentation, as required for the technology’s operation, was installed for proper control and safety monitoring. This included an ultraviolet scanner to detect flame on the surface and oxygen control.

Results

After the solution was installed and commissioned, data was collected to verify NOx performance under typical process conditions experienced at the refinery. NOx data was obtained using an analyzer with a low-NOx cell. Flue gas samples were drawn from the furnace stack and were conditioned using a sample dryer with a fast loop. Wet oxygen data was obtained using an in-situ zirconium oxide oxygen probe installed downstream of the convection section.

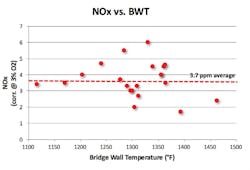

Figure 5. NOx versus bridge wall temperature

More than 100 data points were obtained during a six-week period. Data points presented in Figures 5 through 8 represent averaged daily data.

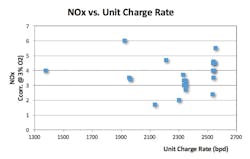

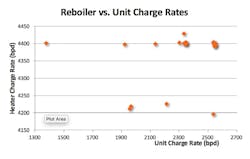

The thermal load in the reboiler process heater is dependent on the reformer unit process conditions. Because of this, refinery operations requested to monitor operation as a function of the unit’s charge rate (barrels per day).

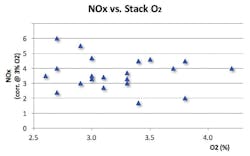

Figure 6. NOx versus zirconium oxide oxygen probe measurement

Daily unit and reboiler charge rates were kept at constant values and experienced only minor daily deviations.

A summary of results is presented in the following graphs:

NOx results met and exceeded project objectives. In addition, average CO emissions were 25 ppm (corrected at 3 percent O2) and were consistently lower than 50 ppm (below regulatory requirements) despite the relatively low bridge wall temperature conditions. Furthermore, performance was stable over all process conditions encountered during the evaluation period.

Figure 7. NOx versus reformer unit charge rate

The NOx data is scattered and does not appear to reveal any trends. However, the dynamic conditions typically encountered in refinery operations in which thermal loads, fuel heating values and other process variables that may change rapidly and may not be monitored continuously make it difficult to establish any trends.

Surface glow can also be used as a qualitative measure of optimal performance.

Figure 8. Reboiler heater charge rate versus reformer unit charge rate

Conclusions

The new combustion technology demonstrated its capability to consistently operate with NOx emissions less than or equal to 6 ppm, corrected at 3 percent O2 (less than or equal to 0.007 pounds of NOx/MMBtu) without external flue gas recirculation or selective catalytic reduction, over a wide range of refinery process conditions. This emissions performance satisfies the most stringent NOx regulations.

Other refineries may be able to use the technology as a solution to eliminate flame impingement on furnace process tubes brought about by long and buoyant flames characteristic of ULN burners.

References

- Karkow, D., et. al. "Duplex™ Technology Demonstrates Sub-5 PPM NOx and CO Simultaneously Without SCR, FGR, or High Excess Air." AFRC 2015 Symposium.

- Breidenthal, R., et. al. (2014) "Radiative cooling in a flame holder for NOx reduction." American Physical Society Division of Fluid Dynamics, Fall 2014 APS.DFDA34005B.

- "Thermal Radiation Heat Transfer," R. Siegel & J. Howell, Published by Taylor & Francis, 4th Edition, 2002.

Roberto Ruiz, Ph.D., is chief operating officer (COO) for ClearSign. He previously served as president and COO for OnQuest Inc. Ruiz received a Bachelor of Science in Engineering from the University of California, Los Angeles, a Master of Science and Ph.D. in Mechanical Engineering from the University of Minnesota, and an M.B.A. from the University of Chicago. Ruiz may be reached at [email protected].

Donald Kendrick, Ph.D., is chief technology officer (CTO) for ClearSign. He previously served as director and CTO of Lean Flame Inc. Kendrick holds a Bachelor of Science in Mechanical Engineering from the University of British Columbia and a Master of Science and Ph.D. in Mechanical Engineering from the California Institute of Technology. He may be reached at [email protected].

Learn more at clearsign.com/our-team.