The idea behind turbine meters is quite intuitive. Turbine meters have a spinning rotor with propeller-like blades that is mounted on bearings in a housing. The rotor spins as water or other fluid passes over it. The rotor turns due to the force of the current. Flowrate is proportional to the rotational speed of the rotor. A variety of methods are used to detect the rotor speed, including a mechanical shaft and an electronic sensor.

Turbine meters differ according to the design of the spinning rotor. Several variations include paddlewheel meters and propeller meters. Paddlewheel meters are based on the idea of the water wheel and have a rotor that has an axis of rotation that is parallel to the direction of the flow. Many paddlewheel meters are insertion types. Propeller meters, which typically have only a few blades, have a rotor that is suspended in the flowstream.

What turbine meters have in common is the use of a rotor that spins or rotates in proportion to flowrate. Measuring flow in this way requires the capability of detecting the rotational speed of the rotor. For this reason, the turbine meter as it is used today had to await the invention of a pick-off sensor with a magnet and a rotating conductor. This made it possible to count the number of rotations of a turbine rotor. It wasn’t until World War II that turbine meters came to be widely used. They were used on military aircraft during this time to measure fuel consumption. Soon after this, they began to be used to measure the flow of hydrocarbons.

The use of turbine meters to measure gas flow dates back to 1953. Rockwell introduced an improved turbine meter to the gas industry in 1963. It took about 10 years for turbine meters to become accepted by the gas industry for measuring gas flow. The American Gas Association (AGA, aga.org) published its report #7, “Measurement of Fuel Gas by Turbine Meters,” in 1981. Since that time, turbine meters have been solidly established in the gas industry, especially for custody-transfer applications.

Types of Turbine Meters

The following are the main types of turbine flowmeters.

-

Axial

-

Single-jet

-

Multi-jet

-

Paddlewheel

-

Pelton wheel

-

Propeller

-

Woltman

Axial turbine meters have a rotor that revolves around the axis of flow. Most flowmeters for measuring industrial liquids and gases and for oil measurement are axial flowmeters. Axial meters differ according to the number of blades and the shape of the rotors. Axial meters for gas measurement have a different design from axial meters for liquid applications. Axial turbines are the most common type of turbine meter.

Jet turbine meters are primarily used for municipal water measurement, although some are also used for commercial and industrial water measurement. Jet meters are of two types:

-

Single-jet

-

Multi-jet

Single- and multi-jet meters have one or more orifices that direct a stream or “jet” of water onto a set of blades, causing them to turn. Single-jet meters have a single orifice, while multi-jet meters have multiple orifices causing streams of water that cause a rotor to revolve.

Paddlewheel turbine meters have a lightweight paddewheel with flat blades that spins in proportion to flowrate. They are used for measurement of low-speed flows. Paddlewheel meters look like a water wheel and are mounted so that the spinning wheel only dips into a portion of the flowstream. For this reason, many paddlewheel meters designed for larger line sizes have adjustable insertion depths. Paddlewheel meters are mounted at right angles to the flowstream, and the shaft and bearings are outside of the flow.

Pelton wheel turbine meters work somewhat like paddlewheel meters, but have a single size rotor with straight blades. Pelton wheel meters are based on the original Pelton wheel that was used to turn turbines with flowing water. The original Pelton wheel had bucket-like containers mounted on the wheel that caused the wheel to rotate when water flowed over the wheel. Today’s Pelton wheel meters have a similar but more compact design and are used mainly to measure the flow of low-viscosity fluids at low flowrates.

Propeller turbine meters are bulk meters used mainly to handle dirty liquids. Propeller meters have helical-shaped blades that are longer than the blades of most other turbine meters. They also have fewer blades than the rotors of most other turbine meters. Propeller turbines were first invented by Forrest Nagler in 1916, and they resemble the wooden propellers found in boats. Because they have few blades, they can more easily handle debris and are among the most rugged of turbine meters.

Woltman turbine meters have a turbine whose axis is in line with the direction of flow. Woltman meters are water meters used for larger volume applications. They are sometimes called “bulk” meters and are quite accurate.

Two other types of meters that are difficult to classify also bear mentioning here because they incorporate turbine technology: compound meters and fire service meters.

Compound meters are difficult to classify because they are hybrid meters that incorporate two different technologies. Compound meters are designed to handle both high and low flowrates, and they are often installed in apartment and office buildings that experience periods of high-flow use and low-flow use. For example, in a large apartment building, flowrates are likely to be very high in the morning and evening. They will be much lower in the day and at night.

Compound meters often incorporate turbine technology for high flowrates and positive-displacement (PD) flow technology for low flowrates. Because PD meters are very accurate in measuring low flows, the PD component of a compound meter measures flow during the off hours. During peak usage, the turbine meter does the measuring. However, some compound meters use jet-type turbine technology for the low flowrates, making them a type of dual-turbine technology meter.

Fire service meters are used in commercial buildings where there is the need to handle very high flowrates, such as would be experienced when using water from a hydrant to fight a fire. Many fire service meters incorporate turbine technology.

Applications for Turbine Flowmeters

Commercial Use: PD meters dominate the residential flowmeter market, although single-jet and multi-jet turbine meters are also used to measure water flow in private homes. Turbine meters are more typically used to measure water flow in office buildings, hotels, apartment complexes, and other commercial buildings. These buildings are a good fit for single-jet or multi-jet meters, and they may also use Woltman or compound meters, depending on the load.

Submetering: The increased cost of water and the increased size of apartment and office buildings have generated the practice of submetering. Submetering typically takes place in a large apartment building or office with many tenants where tenants are individually metered for their water use. This can occur just as easily for offices as for apartments or condos. Submetering allows the owner of the building to pass along the costs of water use to the tenants, based on their actual usage. Some companies specialize in submetering, and single-jet or multi-jet turbine meters are often used for this purpose.

Industrial use: Turbine meters are used to measure water use at industrial plants, as well as at commercial businesses. This is a utility measurement; however, since it occurs at a manufacturing plant, it is an industrial measurement. Other types of meters used for this purpose include magnetic, vortex, and differential pressure (DP).

Comparison to PD Meters

Turbine flowmeters are used when the line sizes are larger and the flow volume is greater than can be handled by PD meters. One of the main differences between PD meters and turbine meters is that PD meters do better with low flowrates and low-flow volumes, while turbine meters excel with medium to high flowrates and flow volumes. Therefore, turbine meters are often used in the larger line sizes, especially those exceeding 4 inches.

Oil: There is a very large market for measuring the flow of oil, refined fuels, and hydrocarbon products. One group of suppliers is focused on providing meters for loading and unloading trucks, tankers, airplanes, and ships. Most of this measurement is for the purpose of custody transfer. This measurement occurs both upstream and downstream of refineries. Oil trucks that deliver oil to businesses, ships, and aircraft use a flowmeter to measure the amount of oil dispensed. Both PD and turbine meters are used for this purpose. Turbine meters are used for the lighter, less viscous oils, while PD meters are used for flow measurement of heavier, higher viscosity oils. Coriolis meters are now increasingly being used for these applications as well.

Process Liquids: In addition to water and oil, turbine meters also are used to measure process liquids. These include pharmaceutical chemicals, paints and varnishes, dairy products, industrial chemicals, cosmetics, printing ink, and many other liquid products. In many cases, turbine meters provide a highly accurate measurement at a favorable cost relative to other meters, such as Coriolis or magnetic. Turbine meters are used for higher flowrate measurements, while PD meters are used for measurement of flow at lower flowrates. Coriolis meters are sometimes used when high accuracy and long-term reliability are major considerations.

Gas: Turbine meters are used as a billing meter to measure the amount of gas used at commercial buildings and industrial plants, as well as in custody transfer and non-custody transfer applications of natural gas in upstream and downstream production environments. Examples of commercial buildings that use gas flowmeters for billing are hotels, apartment buildings, and office complexes. Industrial plants such as chemical, food processing, and pharmaceutical plants also use turbine meters for billing purposes. These meters are different from the meters used to measure gas as part of the manufacturing process.

The market for commercial and industrial turbine gas meters for billing purposes or to track usage at a commercial or industrial building is called the municipal gas market. This is a utility measurement. A specific group of companies supplies meters to this market.

Turbine flowmeters are also widely used for custody transfer of natural gas. They are used to measure gas flow on large gas pipelines that carry natural gas from its source to its destination — sometimes for thousands of miles. Turbine meters compete with ultrasonic and DP flowmeters for this important application.

Prospects for Turbine Flowmeters

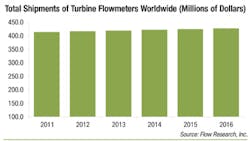

The turbine flowmeter market has been essentially flat for the past 10 years, so the good news is that the market has not been declining, but the bad news is that during this same time period the Coriolis, ultrasonic, and magnetic flowmeter markets have expanded substantially.

Part of the issue with turbine meters is research and development. There is a group of suppliers, including Elster, Cox, Badger Meter, and Hoffer, among others, that are actively researching this market and introducing new features and products. Examples include different bearing types, different rotor designs, dual rotors, and bi-directional capability. Other suppliers continue to offer products, but are not actively engaging in new product development. This prevents the market as a whole from expanding significantly. There is still hope for turbine meters to expand, but this requires a broader commitment by suppliers to offer improved products.

Jesse Yoder, Ph.D., is president of Flow Research Inc. in Wakefield, Mass., a company he founded in 1998. He has 24 years of experience as an analyst and writer in process control. Dr. Yoder specializes in flowmeters and other field devices, including pressure and temperature products. He has written over 170 journal articles on instrumentation topics. Dr. Yoder can be reached at [email protected].

www.flowresearch.com

Flow Research has just published a new market study called “The World Market for Turbine Flowmeters, 2nd Edition.” For more information, see FlowTurbine.com.