We have all experienced the frustration of a problematic sensor, even when the supplier tells us everything seems to be working properly. What we often find is that while the sensor may be “working,” it is often not the right sensor for the application.

Successful pressure measurement usually comes down to one thing—selecting the right sensor for your application. There are so many considerations that it is easy to overlook a key element until it’s too late. Nearly a decade of working with pressure sensors in various applications has convinced me that the most common reason for problematic pressure measurements is the failure to select the right sensor. Even industry veterans can fall into this finespun trap.

This article presents 15 fundamental considerations when selecting a pressure-sensing device.

1. Pressure Range

The pressure range is perhaps the most fundamental of all considerations when selecting a pressure transducer. Typically, the highest pressure a sensor is likely to experience is considered the pressure range required for the application—the full-scale pressure range of the sensor.

There are two schools of thought:

First, you could use a sensor with a range that matches the application. In such a case, the application pressure equals the sensor pressure range. This approach is the most intuitive and fairly common.

For applications where the sensor is being used for process control purposes, such as tank level measurement, the closer the sensor range is to the application range, the better. Such applications do not see huge pressure spikes and usually operate through a wide area of the pressure spectrum—not always at maximum pressure.

Second, you could down range the sensor by going with a sensor pressure range that is higher than what is required by the application. If frequent bursts or spikes in pressure can occur beyond the application pressure range, then it could be advantageous to down range the sensor. It may also be a good idea if the pressure is at or near maximum most of the time.

Down ranging means that a sensor is selected with a higher pressure range and the manufacturer calibrates the output to match the desired application pressure range.

This results in reducing the sensor resolution, and if too low, it will affect the performance accuracy of the sensor. How far to down range a sensor is completely subjective. However, the application pressure range is typically 75 percent of the full-scale range of the sensor. Following this rule-of-thumb will generally keep you out of trouble.

While neither approach is inherently right or wrong, it is important to understand the pressure characteristics of the application before selecting the pressure sensor range.

2. Pressure Type

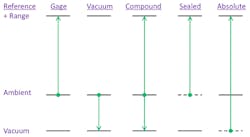

There are several pressure types to consider, but they can all be divided into two broad categories—vented and sealed.

Vented pressure types use atmospheric pressure as the reference point, or the zero point. By definition, vented sensors are not affected by barometric or elevation changes as they are vented to atmosphere. The reference point becomes whatever the barometric pressure is at the time, and is therefore immune to these changes.

The vented category includes:

- Gage: Gage sensors begin at zero and measure pressure up to their rated full-scale pressure range.

- Vacuum: Vacuum sensors measure from zero to a full vacuum, not exceeding -14.75 PSI.

- Compound: Compound pressure sensors measure from full vacuum pressure to the full-scale pressure range.

Sealed sensors have a sealed reference point that everything is measured against. As such, they are influenced by changes in barometric pressure and elevation. The zero point of these sensors is the pressure under which the sensors were sealed.

The two sealed pressure types are:

- Absolute: An absolute sensor is sealed under a full vacuum, which becomes its zero point.

- Sealed: A sealed sensor is sealed under whatever the atmospheric pressure was at the time. This is usually done to protect the sensor from moisture and dust.

The higher the pressure range, the less impact this decision will have on sensor performance. For example, at 5,000 PSI, the approximate 15 PSI difference between an absolute sensor and a gage sensor is usually insignificant.

I would suggest the pressure type be considered very carefully in any pressure range below 1,000 PSI, as the small changes in atmospheric pressure become a greater percentage of full-scale. The questions to ask are:

- Where do I want my zero reference point to be?

- Do I want it to change with barometric pressure?

3. Output

An array of output options is available. Your choice depends on whether the sensor is used in conjunction with a controller, or is a stand-alone unit. If using a controller, make sure it can handle the output offered by the sensor manufacturer.

Stand-alone sensors, such as a digital pressure gauge, usually come with a visual display, but can also include an electrical output, and can still be used in conjunction with a controller.

Again, match the output of the sensor to the input requirements of the controller.

4. Accuracy

While price is not actually one of the considerations addressed in this article, accuracy is perhaps the key factor in driving the cost of a pressure transmitter. The higher the accuracy required, the higher the cost. By carefully examining what accuracy is required for the application, you are, in fact, limiting the expense of your project.

After defining the accuracy needs of the application, you must ensure that you understand how your accuracy calculation method matches up with how the prospective supplier calls it out on a datasheet.

For example, if you are calculating using a straight-line or terminal end-point method, it is not the same as a best-fit-straight-line (BFSL) method. In addition, some manufacturers combine linear performance, hysteresis, and repeatability in the accuracy specification while others call them out separately.

I am not advocating one method over the other; just make sure you understand how the sensor specification matches up with your requirement.